Determination of local temperatures of goods in stacks by using a porous media approach

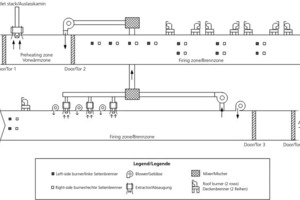

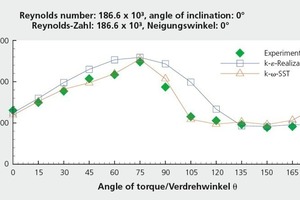

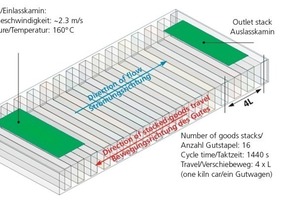

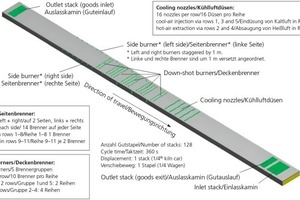

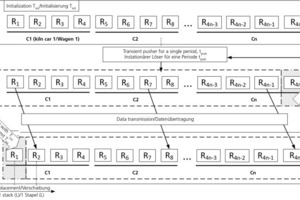

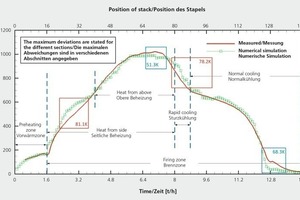

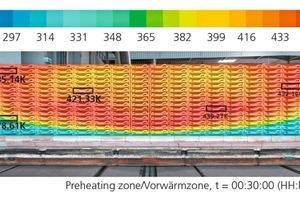

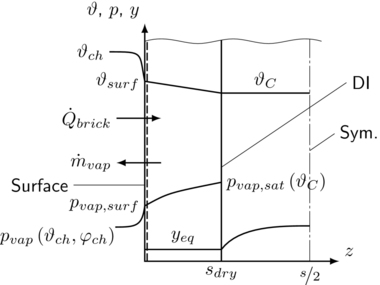

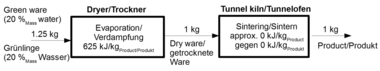

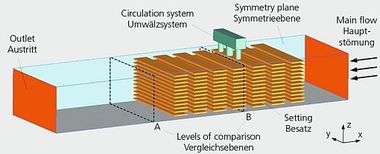

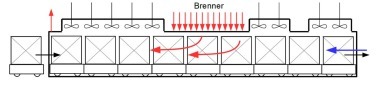

The article describes a numerical methodology for modelling the complete firing process in an industrial furnace. A three-dimensional model based on the finite volume method is presented and applied to the process. The homogeneity assumption “porous medium” is used to simplify the size of the computational domain and the required computational time. The effective properties of the porous model body are calculated and transferred to the simulated structures. The temperature profile in the furnace and the temperature distribution in the stacks can be calculated with the use of this model in an acceptable time. The numerical results are compared with experimentally measured values. A good agreement is found.

1 Introduction

For all industrial manufacturing processes, one aim is to reduce energy consumption. With regard to thermal process technology, both the builders and the users of furnaces endeavour to reduce their installations‘ fuel requirements. One fast, economical means of better understanding and visualizing the processes that take place within such furnaces in the course of heat treatment and firing processes is referred to as numerical simulation [1, 2].

For a real process, direct numerical simulation reaches its present limits. This is due to the complexity of the geometric structures,...