Die casting of special shaped bricks

Accessory roof tiles that cannot be produced by pressing are either luted by hand and “cemented“ by firing or cast by hand with very long setting times.

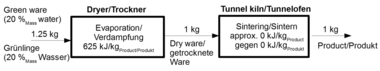

However, such a complicated production process can be avoided, and such long setting times extremely abbreviated, while expediently die casting as an integral whole all the parts that used to require subsequent assembly. Taking a mono-pitch tile as an example, this project investigates the potential suitability of the die casting process for products like roof tiles. The process is based on a pressure-die-casting composition consisting, apart from the electrolytes, exclusively of roof tile casting materials. The die casting tool was manufactured according to the rapid tooling process. Starting from a model, two blocks of polymethyl methacrylate are milled out to obtain the die halves. Such dies, including multi-part versions, can be plain cast, with casting times of five minutes for accessories being readily achievable, and multiple cavity dies can be used to further accelerate productivity. The application is also suitable for complex façade elements.

Thus, the die casting process is well suited for application to the manufacture of roof tiles and façade elements, and it is economically feasible for producing certain, particularly complicated shapes.

Dr. Jens Petzold, KI Keramik-Institut GmbH