Faster from research to the finished product

Nowadays, 3D printing makes things possible that engineers and mechanical engineers only dared to dream about for a long time. In various fields of application and disciplines, the technology is increasingly capable to optimise traditional processes, even replacing them completely. A special 3D printing process has been applied for further developing of modern high-precision bricks at the Mein Ziegelhaus research centre of small- and medium sized enterprises in Höhr-Grenzhausen for some months now. In this process, however not the bricks themselves emerge from the printer, but the extremely stable dies for the so-called extrusion tools which are in turn essential for the production of high-precision masonry bricks. At the end of the extrusion press, they ensure a perfect flow behaviour of the still unfired clay and create the requested hole patterns during extrusion.

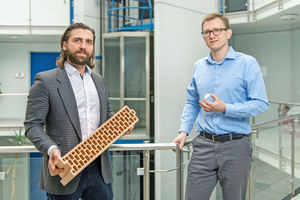

„We know from our research work that even minor changes of the hole pattern of the brick allow for optimising several properties in terms of building physics,“ explains Dipl.-Ing. Tristan Klein, General Manager of Mein Ziegelhaus. So far, making modifications had however been expensive and, above all, time-consuming. Hence, every hole pattern required individual and complete manufacture of a steel extrusion tool. A process that can take up to six months. 3D printing shortens this period to just two to three weeks. Another new aspect of the procedure is that only small ceramic elements are printed individually, which are then inserted into the existing extrusion tools. Klein states, „Now, 3D printing enables us to respond to current research findings quickly and to be able to make adjustments to the extrusion tools at short notice.“

Harder than steel

The procedure of the brick manufacturing process itself remains unchanged. Since the raw material, a mixture of argillaceous loam, is pressed through the extrusion tools at the outlet of the extrusion press by means of an enormous pressure, the printed dies need to match very strict requirements. In addition, the ceramic brick mixture permanently streams past the extrusion tool dies and has a strongly abrasive effect on all components. After different tests conducted together with the joint project partner, Hilgenberg-Ceramics GmbH & Co. KG specialised in industrial 3D printing technologies, Mein Ziegelhaus opts for dies made of high-purity aluminium oxide. Their strength is comparable to the hardness of a sapphire. Consequently, they are resistant to abrasion for a longer period, and therefore they have a much longer service life than steel.

Decisive for the process reliability and quality of the brick production is the homogeneity of the flow inside the extrusion tool. Thanks to 3D printing, every single extrusion tool die can be adjusted individually, thus avoiding the typical defects such as cracks, bubbles, uneven surfaces and so-called dragon teeth.