Hybrid dryer

TCKI has developed a new drying process for chamber dryers (hybrid dryers) that can reduce the specific annual energy consumption for drying from approx. 4 000 to roughly 3 000 kJ/ kg water.

It therefore fits nicely into the „plant of the future“ with a minimized CO2 footprint. The results of research conducted on TCKI‘s pilot dryer, viewed in the light of kiln-supplier recommendations, show that the best outcomes are obtained for a combination of volume dryers and tunnel kilns with little or no thermal discharge.

The TCKI pilot dryer makes it possible to convincingly establish, for each individual product, the drying process and drying curve promising the lowest energy consumption, even for existing dryers with rotary fans.

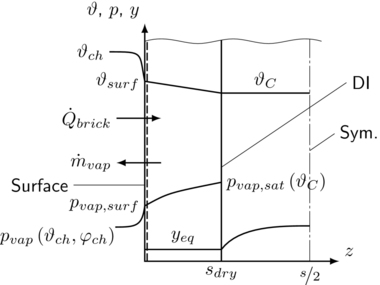

The hybrid drying process begins with aerothermal drying by ambient air (if possible), followed by semi-steam drying at high temperature and atmospheric moisture.

The first project is being implemented by Instalat (NL) at Joseph Bricks in Maasmechelen (B).

Dr.-Ing. Hans Marks, TCKI, Velp, the Netherlands