Impure raw materials as a source of defects in building ceramics – analysis with scanning electron microscopy

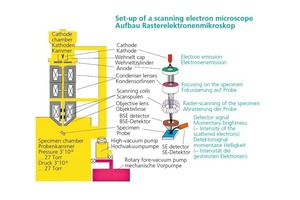

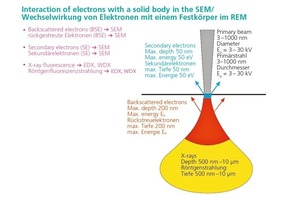

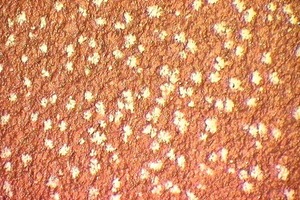

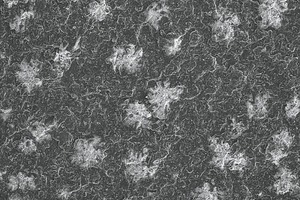

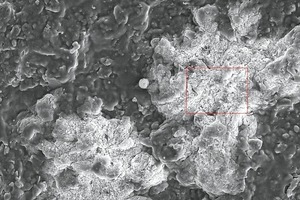

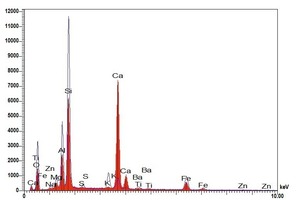

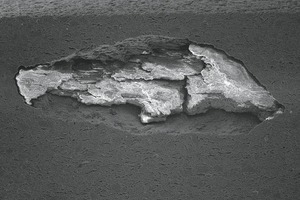

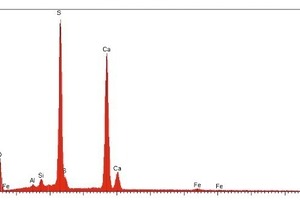

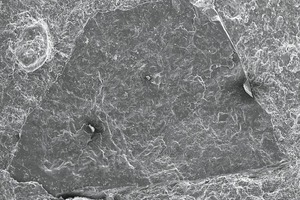

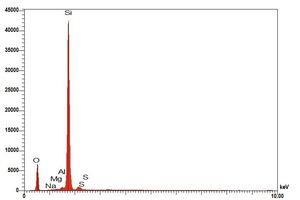

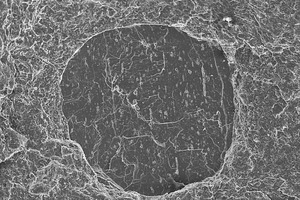

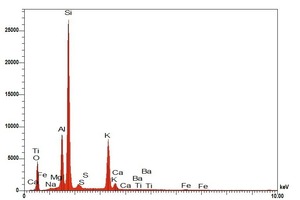

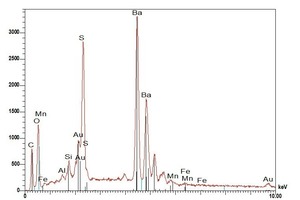

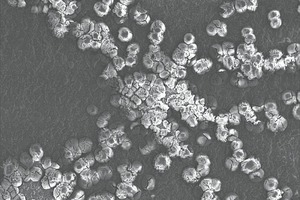

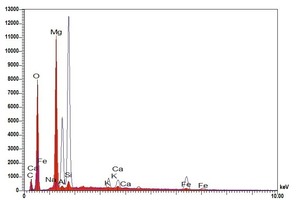

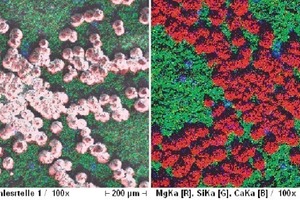

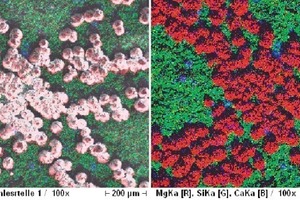

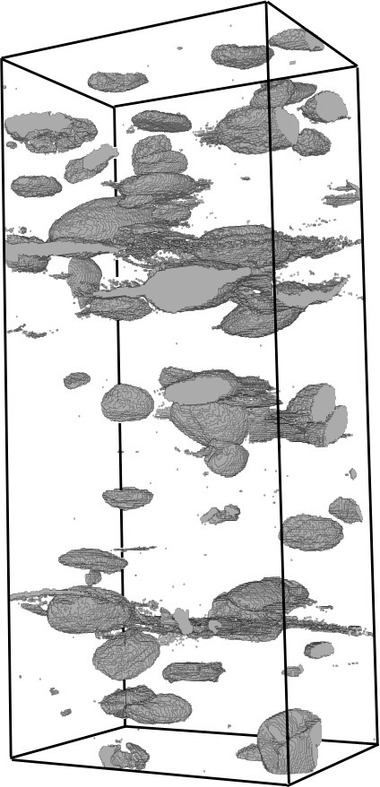

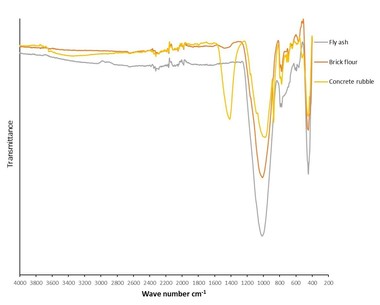

This paper provides an insight into analysis methods with the use of scanning electron microscopy. The set-up and operating principle of the scanning electron microscope (hereinafter referred to as SEM) are described and the interaction between the electron beam and the specimen are explained. Based on three examples, two instances of efflorescence on natural red clay roofing tiles and coarse components as the cause for spalling, the procedure and possibilities for analysis with the SEM are illustrated.