It takes patience – the 24-year success story about the counterflow kiln at Ziegelwerk Huber

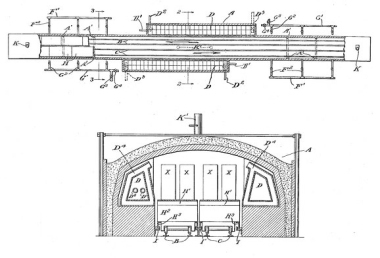

Back in the autumn of 1989, we heard about Riedel’s counterflow kiln through the East German trade press grapevine. While some were touting it as an innovative kind of tunnel kiln, some even as an eco-tech tunnel kiln, others knew for sure from “knowledgeable sources” that it was nothing more than a “half-baked idea” that would never work, because: “Things just are not that simple!”.

At the time, not one single kiln in all of Germany had ever been built strictly according the Riedel kiln construction principle. The system was “untested” and, hence, unacceptable for respectable brick people. At Huber‘s brick factory, though, such a kiln was put up despite all the dire warnings (according to which, since a brickmaker only builds one kiln in a lifetime, it better be the “right one”) and all the technical advice to the contrary.

We were not afflicted with too much money, nor did we consider ourselves too smart to heed the informed opinions and collective experience of our peers. We simply understood the logic behind the kiln‘s thermal gravity principle so well, that we were practically electrified and thoroughly convinced that we wanted to build just exactly this counterflow kiln and no other.

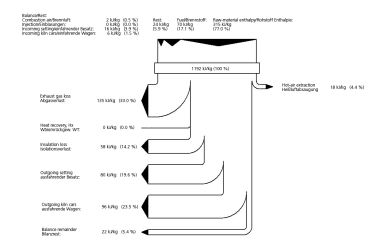

So, together with the project‘s intellectual father, Rudolf Riedel, we built it and found that we just could not imagine it needing any further optimization. It does what it is supposed to do, and it keeps all its promises. Its design principle is simple and easy to fathom, it is rock solid and unbelievably stable, shows robust firing behaviour, scrimps on energy and is versatile, simple to operate and easy to maintain.

Now, 24 years of operation and lots of experience later, we would do it all again if we had to – despite all the same old, almost incredulous questions that are still being posed about the system‘s performance. Out patent answer: “Yes, things really are that simple, just a little hard to grasp.” This kiln is one system that has been fascinating the experts for over 25 years.