Lingl supplies new-generation technology to Briqueteries de Ploegsteert

The Belgian brick manufacturing company Briqueteries de Ploegsteert has equipped its factory with a Turbo II Modular Grinding Center and a Coriso Filling Installation supplied by Lingl. Ploegsteert makes facing and backing bricks as well as concrete ceiling elements and ceiling blocks. It is based in western Belgium near the French border and supplies the domestic market and the adjoining French market with its products.

This is the first project at Ploegsteert in which Lingl’s new machine technology has been installed. Lingl, a leading supplier in the field of grinding technology for heavy clay ceramics, installed the “Grinding Center Turbo II” with a two-module structure for grinding backing bricks. This machine ensures high throughput rates combined with ease of operation by means of a mobile control panel and high flexibility for the future extension of the system thanks to its modular design. Depending on market and capacity requirements, it is possible to equip the modular grinding center with up to four modules.

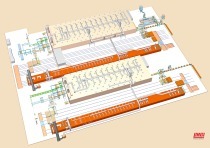

With regard to sustainability and technical innovation, Ploegsteert decided on a Lingl Brick Filling Installation for Unipor Coriso bricks. The order volume for the system for conveying and filling wall bricks with mineral granulate includes the transport equipment, the granulate supply and infeed, the storage and the dosing of the mineral granulate as well as the extraction equipment. This investment for a brick filling line is Ploegsteert’s first step into brick filling technology and thus an investment for the future.