Modern brickwork masonry embedded in heritage-protected farmstead

The training farm operated by the Birkeneck Youth Support Organization belongs to heritage-protected Birkeneck Manor. It is situated directly across from the manor's 1706 structure. The Missionaries of the Sacred Heat assumed possession of the estate in 1925. Ever since, in the spirit of Founding Father Jules Chevalier, the order has been offering troubled youths multifarious forms of training and support. The fact that the facility was legally converted into an independent, public-benefit sponsor of youth welfare services in the year 2000 did nothing to change that cause.

Partial reconstruction necessary

In recent years, part of the U-shaped group of estate buildings was converted into workshops and training rooms, as exemplified by the head-end tract. Basically, only the southern tract was left out at the time. This was because a detailed inspection of the building fabric in 2002 revealed substantial static deficiencies in the open-beam ceilings and extensive moisture-penetration damage in the walls and roof-supporting structure. If used according to plan as a sociotherapeutical dwelling house, the structure would have had to carry substantial additional weight, but the existing walls and floors were not designed for such loads. The scope of the problem and work to be done made a conversion appear economically unreasonable. Thus, the old building stock was torn down completely on a length of about 35 meters, and the rest (56 meters) was relieved of its upper storeys and roof.

Very glassy roof

The gap left by the demolition work was then filled out with a new brick structure. In order not to disrupt the appearance of the heritage-protected ensemble, the new building was given two full storeys and a fit-out attic - all adding up to the same size and shape as that of the remaining farmstead array. The window heights and ridge line also correspond to those of the remaining listed building tracts.

Mathias and Stefan Rentz, the architects responsible for planning and supervising the project, focused not only on the conservation-appropriate prescriptions, but also on modern design elements that would be capable of accentuating the new structure's independence - of which the large dorm windows and fitted ridge windows are the most notable. As Stefan Rentz explains, "The glass elements let daylight flood the loft and give the room a nice, well-lit ambience." Massive, heat-storing roof tiles in combination with solar-retarding roll-film coatings on the glass elements and an energy saving, heat-exchanging ventilation system all work together to keep the rooms from overheating.

High thermal protection with no additional insulation

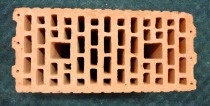

Since the walls of the torn-down part of the building consisted of solid-brick masonry, it seemed only logical to use clay masonry for the new construction, too. "Orientation on the original wall-building material, though, "the architect explains, "was not the decisive factor. Modern "bricks", i.e., clay masonry units, have little in common with their historic predecessors in terms of appearance and, in particular, physicostructural qualities. The employed Unipor-W14 aerated high-precision clay masonry units, with their high thermal insulation, load-bearing capacity and good processability, produced very convincing results."

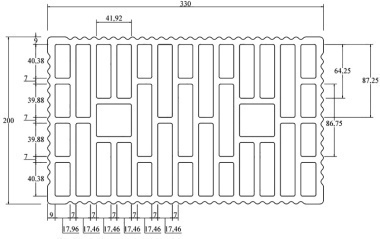

The masonry's low thermal conductivity (λR = 0.14) and apparent specific density (0.9 g/cm³) were not secured at the cost of compressive strength but from an ingenious core pattern and purposeful aeration. Including its interior and exterior rendering, the 36.5 cm masonry achieves a U-value of 0.35 W/m²K. Consequently, no supplementary (costly) insulation is required for the exterior walls. Moreover, thanks to the blocks' flat-ground bearing faces, thin-bed mortar can be used - meaning further cost reduction and additional economic benefits. The result: high-quality masonry with bearing joints measuring one single millimetre and containing 85 percent less mortar than would have been required for conventional brickwork.

Young team of masons

A special feature of this project was the particularly young "team of masons". The apprentices from the "masonry" training department of the Birkeneck Youth Support Organization put in a bid for part of the masonry work in a limited public tendering - and were awarded a contract. "Learning how to put up modern masonry and to apply conventional and rational work methods received the most emphasis," Rentz explains. It did not take long for the young masons to notice and appreciate how easy it is to handle the clay masonry units. The apprentices also quickly learned how much time and energy can be saved by employing rational techniques. For example, using a (unimaxX) mortar sled practically makes child's play out of laying uniform bearing joints (1 mm).

Flat-ground filler blocks

Since the new rooms were intended for use as living and sleeping quarters as well as for noisy sports and leisure activities, the partitions had to be accordingly well insulated. Work therapy in the form of individual artisanal training was also kept in mind as a potential source of bothersome noise. Because the degree of airborne sound insulation that a monolithic wall can achieve is decisively dependent on its weight per unit area, the employed masonry units had to be as heavy as possible. On the other hand, the realities of combustion engineering demand that heavy bricks be small, and that tends to prolong the time required for laying them.

Thus, instead of small, heavy bricks, the choice fell on large-format Unipor hollow clay filler blocks (12 DF). The supplied high-precision clay filler units (apparent specific density 0.9 g/cm³) from Wöhrl GmbH – a member of the Unipor Group - are relatively light, because they have four filling chambers. Thanks to their superior dimensional accuracy and flat-ground bearing faces, they were just as easy for the apprentices to quickly lay in thin-bed mortar as the exterior wall units were.

The freshly laid 24-cm partition walls were filled with normal concrete weighing 1.8 kg/dm³ to arrive at a final weight per unit area of 486 kg/m². The finished partitions achieved a sound reduction index (Rw) of 54 decibels.

Open and closed areas

Since its completion in March 2006, the new wing serves mainly as a home for groups of children and adolescents aged 10 to 16 who are receiving all-day sociotherapeutical care. Also, the youth support organization's administration offices occupy some of the ground-floor rooms.

Part of the new wing serves as a clearing point where children under the age of criminal responsibility receive individual psychological care. The clearing-point setting therefore requires secure doors and windows.

Planning and project supervision: architectural engineers Mathias Rentz and Stefan Rentz Clay units from: Wöhrl GmbH Ziegelwerk-Deckensysteme, Berghaselbach 5, Wolfersdorf