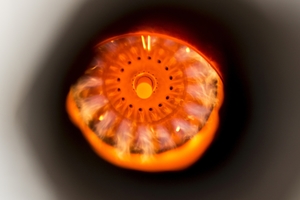

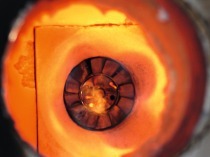

Newly developed bio-multi-fuel burner

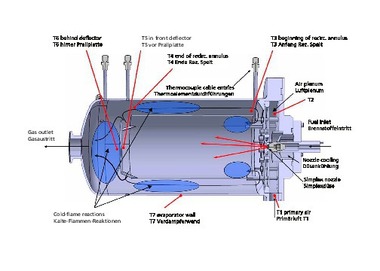

In a joint research project, the Gas- und Wärme-Institut Essen e. V. (GWI) and the OWI Oel-Waerme-Institut (OWI) have designed, manufactured and tested a combined biofuel burner for the generation of industrial process heat.

In addition to low-calorific gases, the burner can also burn liquid biogenic fuels, such as vegetable oil, in an effective, reliable manner with low emissions. The liquid conventional and biogenic fuels are pre-evaporated in a specially developed evaporation reactor.

Initially, a demonstrator was set up with an output of 100 kW, which was scaled to 300 kW during the course of the project. The results achieved show that the bio-multi-fuel burner enables stable simultaneous combustion of the pre-vaporized liquid and gaseous bio-fuels with low pollutant emission levels. In their pure form or as admixture components, biogenic fuels have so far only been used in exceptional cases to provide industrial process heat.

The research results showed that gases and oils produced in industrial processes can be utilized as fuel and applied in both high-temperature and low-temperature applications. These include, for example, tunnel kilns and chamber kilns in the heavy clay and ceramics industries, but also dryers and boiler firing systems, for example for media heating in the low-temperature range. In addition, small and medium-sized companies that operate a wide variety of boilers and drying plants in rural areas without a natural gas infrastructure in the lower output range could thus secure their energy supply with renewable fuels. The bio-multi-fuel burner developed enables the simultaneous use of a large number of gaseous and liquid fuels of different compositions. This high fuel flexibility of the bio-multi-fuel burner can also contribute to tapping local, previously unused biogenic fuel sources with a strongly fluctuating supply chain.

* The IGF project 18188 N/2 of the Gas- und Wärme-Institut Essen e.V. was supported through the AiF within the framework of the programme for promoting Industrial Community Research and Development (IGF) by the Germany’s Federal Ministry for Economic Affairs and Energy pursuant to a resolution of the German Federal Parliament.

www.gwi-essen.de

www.owi-aachen.de