Multi-fuel burner for simultaneous combustion of liquid and gaseous biofuels

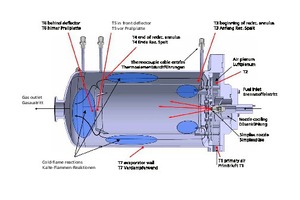

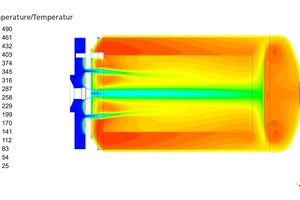

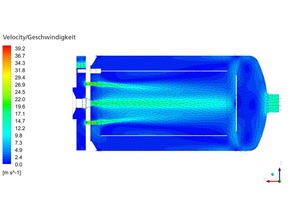

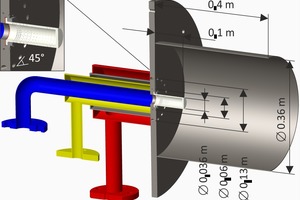

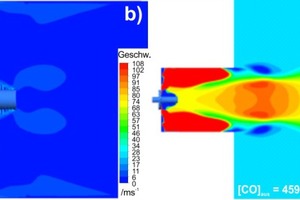

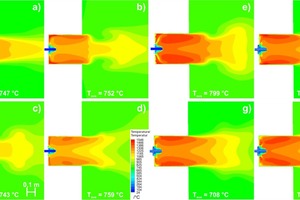

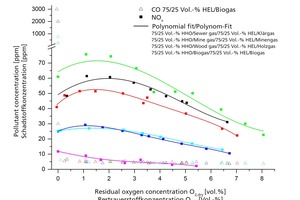

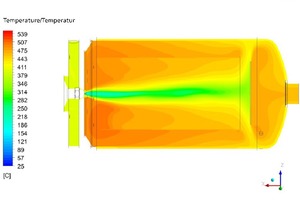

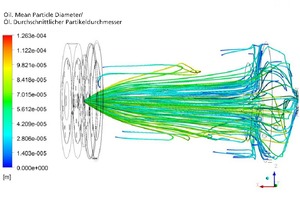

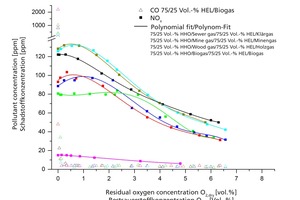

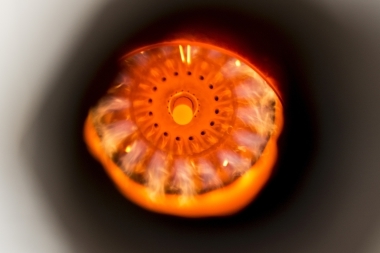

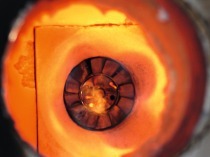

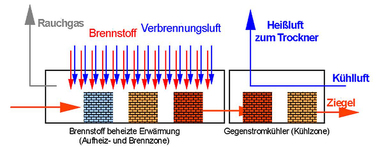

The use of gaseous and liquid biofuels is gaining popularity on the renewable energy market. However, the use of lean gases and liquid biogenic fuels presents a major challenge for the development of burners and thermal processes. Low calorific contents coupled with strongly fluctuating biofuel compositions have major impacts on heat release, flame geometry and stability, as well as on the formation of pollutants during the combustion processes. This contribution presents a combustion system consisting of a fuel evaporator and a downstream, non-premixed swirl burner. The system enables the combined combustion of gaseous and liquid biofuels.

1 Introduction

The recycling and targeted use of biogenic fuels is playing an increasingly important role in the renewable energy market.

Decentralized energy resources such as biogas from fermentation plants, landfills, sewage treatment plants and mines, together with product gases from pyrolysis and gasification plants, offer high utilization potential for the renewable energy market [1]. However, the use of low calorific gases and liquid biogenic fuels derived from renewable resources poses a major challenge for the development of suitable combustion plants and thermal processes [2]. Low...