Novel burner concept for energy saving

in the tunnel kiln

in the tunnel kiln

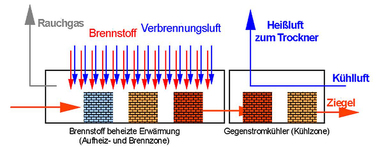

In process terms, modern tunnel kilns in the brick and tile industry involve two coupled subprocesses that take place in succession.

The first of these consists of a preheating process to maturing temperature, in the second process the bricks are brought in a single- or multi-stage countercurrent cooler to exit temperature. The cooling air heated in this process is removed from the kiln process and used in drying of green bricks.

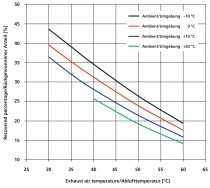

It is known that preheated combustion air leads to an immediate energy saving in the tunnel kiln. If the temperature of this air is significantly high, there are, however, on account of the expense for insulated pipelines, special fans or fittings, great concerns with regard to pursuing this concept. In addition, because of possibly higher combustion temperatures, there is the danger of producing thermally induced nitrogen oxides. Goal of a joint research project between the Gas-Wärmeinstitut Essen, the Brick and Tile Research Institute Essen Regd, the company Lingl and Bellenberg brickworks was to develop a type of burner that uses the hot cooling air in the kiln and therefore contributes to energy saving without the need for costly additional installations. With the design of the burner nozzle, both the homogenization of the kiln atmosphere and avoidance of increased nitrogen oxide emissions must be ensured. With the help of numerical simulation, the flow inside such burners was optimized before production of the burners began. Tests at both institutes accompanied optimization of the burners before they were installed and tested in a real tunnel kiln. The results are presented in the talk.

Dipl.-Ing. Eckhard Rimpel, Institut für Ziegelforschung Essen e.V.