Progress in the recycling of masonry rubble (Part 2)

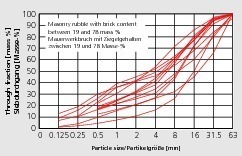

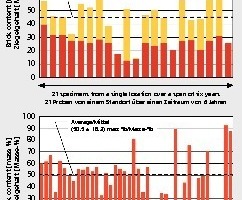

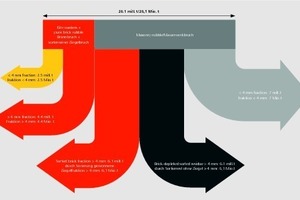

Present practice in the recycling of masonry rubble cannot claim to be contributing to resource efficiency. Building on a 2003 review article on the recycling of masonry rubble [5], this contribution reports on new findings and current developments of relevance. The characteristics of “masonry rubble“ as a material flow category are described, and current research findings and extant technologies explained.

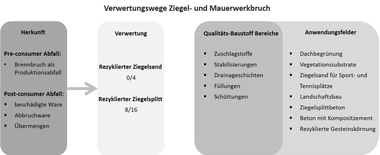

4 Use of brick and masonry rubble as raw material

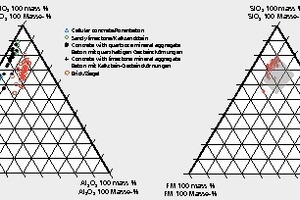

The term material salvaging, or feedstock recycling, describes the use of recycled material in a transmutating process. In the present context, the chemical composition and reactivity of the material are of key importance, while material properties considered to be important for the aforementioned utilization methods fade into the background. Superfine and fine-grained starting materials can be processed. With sole respect to such construction material production processes as brickmaking or cement production, brick and masonry rubble can be...

![»1 Year-2010 incidence of construction waste acc. to [6] and breakdown of building rubble based on [7]](https://www.zi-online.info/imgs/tok_7f1b9b55792f8ec67e16cc159e903098/w300_h184_x251_y92_101487303_29c8e59884.jpg)