Optical sorting of brick and masonry rubble with the use of machine learning processes

Summary

Current guiding strategies and environment policy goals are increasingly demanding the introduction of material cycles from the producers of mineral construction products. From the perspective of construction materials technology, the increasing heterogeneity of mineral construction and demolition waste, which makes up well over a third of all waste types generated in Germany and Europe, presents a formidable problem. For high-grade recycling, a sufficiently high purity of the mineral construction and demolition waste is a basic precondition.

In the project, a demonstrator for the sorting of masonry rubble in the size range of 2 – 8 mm was set up and equipped with identification algorithms in combination with imaging processes. This can be used for differentiation as well as separation of different clay brick and tile types (clay block [HMZ], facing brick [VMZ] and roofing tile [DZ]) on the basis of their optical features.

1. Introduction

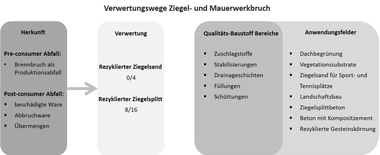

The construction industry is under mounting pressure to minimize its impact on the environment and complete the transition to a recycling economy. One key aspect of this is the optimization of the recycling and reuse of building rubble, which makes up over a third of the total waste generated in Germany and Europe. Especially significant is mineral-based construction waste, like clay bricks and masonry rubble (»Fig. 1), which account for a considerable share in the total waste produced. In Germany alone in 2022, 207.9 mill. tonnes mineral construction and demolition waste were produced, including around 10 mill. tonnes of brick and masonry rubble [1]. This stream of waste offers considerable potential for high-grade recycling applications, especially in building construction [2] – [4].

Although Germany reports a high recycling rate for mineral construction and demolition waste, a large part of this material is used for low-grade applications, like road and path construction or backfilling [5], [6]. This practice takes away from the potential ecological and economic benefits that can be achieved with high-grade recycling and limits the use of recycled material in applications such as concrete or clay brick and tile production [7]. During the deconstruction of buildings, a mix of diverse materials is produced, which undergoes pre-sorting in recycling plants to recycled aggregate and is subsequently used in road, path, and sports ground construction or as vegetation substrate. Depending on the product group, the quantities of recycled (RC) material that can be added and reincorporated in the production process differs considerably. The quality of the RC material that can be reused is also oriented to the specific use. While for clay blocks, an addition of up to 25 % RC material in new brick products is readily acceptable, for clay roofing tiles any addition is limited to 3 % at most [8]. Precondition for this, however, is the exclusion of any mortar stuck to the RC material or other impurities.

On account of its heterogeneity, brick and masonry rubble presents a formidable challenge for the recycling process [9]. Impurities like render and mortar stuck to the rubble make it difficult to achieve the material purity necessary for high-grade recycling. With conventional mechanical sorting processes based on physical properties like density, it is difficult to separate these materials efficiently. For this reason, sensor-assisted optical sorting processes have become increasingly important in recent years [10] – [14].

In the IGF project no. 22068 BG, a demonstrator was set up for the sorting of masonry rubble in the size range of 2 – 8 mm. With the help of specially developed identification algorithms in combination with imaging techniques, this enables the classification as well as separation of different clay brick types (clay blocks [HMZ], facing bricks [VMZ] and roofing tiles [DZ]). Impurities, too, are reliably identified and can be removed. Unmixed brick recyclates can therefore be separated and returned to brick production as well as other applications in the mortar, cement, and concrete industry.

2. Materials and demonstrator

2.1. Materials of the dataset

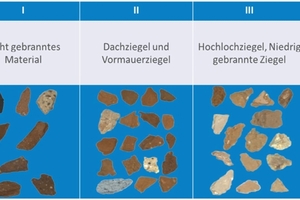

For the training of various classifiers used in machine learning, a total of 59 samples (recycled and as new) were entered into a database with their construction material, image analysis and spectral characteristic data. Another ten samples were used to evaluate the identification algorithms. The collection comprised impurities along with high-fired bricks (DZ and VMZ) and low-fired bricks (HMZ). The samples were analysed to determine their physical, chemical, and mineralogical properties.

For training of the sorting system, the brick samples were allocated to five different categories on the basis of their construction material properties and their potential for reuse:

Category I: unmixed, high-fired material (clinker),

Category II: unmixed hard material (DZ and VMZ with ρb > 2.0 g/cm³),

Category III: soft material (HMZ with ρb < 2.0 g/cm³),

Category IV: masonry rubble and

Category V: impurities like concrete, mortar, and render.

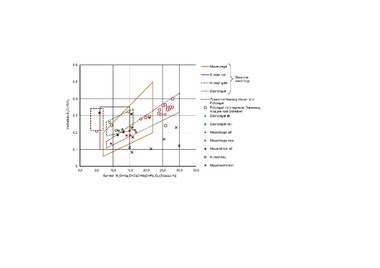

»Fig. 2 shows the relationship between the density and the 24-h water absorption for different sample categories. High-fired brick products (Category I and II) exhibit higher density and lower water absorption. In contrast, low-fired bricks (Category III) exhibit lower density and higher water absorption, which can be attributed to their higher porosity. The impurities (Category V) are more heterogeneous in their composition and therefore vary more widely. The masonry rubble mixes (Category IV) are not included here.

2.2. Demonstrator

The demonstrator shown in »Fig. 3 enables the continuous feed and transport of particles on a conveyor belt as well as classification in real time with the help of RGB images, machine learning classifiers and a synchronized, software-controlled, mechanical discharge system. The RGB line camera ensures fast and high-precision imaging while the particles move along the belt conveyor. The particles with a size of 2 to 8 mm are transported on a linear vibrofeeder so that a uniform distribution and orientation are ensured and the risk of overlapping or misalignment of the particles is minimized. The lighting system consists of two LED light bars with cylindrical lenses, which are arranged at a 45° angle to the belt conveyor to evenly distribute the light, reduce shadows and highlight the surface textures of the particles. From the preprocessed images, a large number of image characteristics concerning colour, texture and shape is calculated. On the basis of these features, the machine learning models (classifiers) were trained so that it is possible to differentiate between the particles based on their optical properties. The classification model was based mainly on a Support Vector Machine (SVM), which proved especially effective in the processing of high-dimensional data and precise differentiation between the categories.

With the demonstrator, a large image data set was created and processed, cross-validation techniques being used to evaluate the performance of the machine learning models.

3. Results

3.1. Selection of a classifier

On the basis of preliminary tests, an SVM with a radial basis function (rbf) kernel was selected as the best suited for the above-mentioned identification application. The SVM is an established algorithm in machine learning, which is used for classification applications. The input data are represented in a higher dimensional space and a hyperplane inserted to separate different classes. The classification performance of the system was analysed based on the identification rate and robustness of the sorting, both trained and non-trained samples being tested.

3.2. Identification and sorting rates for the trained brick samples

The training dataset compiled with the demonstrator (»Fig. 4) was recorded and analysed. As can be seen in »Fig. 5, the system achieved a mean identification and sorting rate of 89.9 %. The sorting rate in most categories reached over 90 %, although Category III reported a lower accuracy of 80.4 %.

3.3. Testing the identification routine on non-trained samples

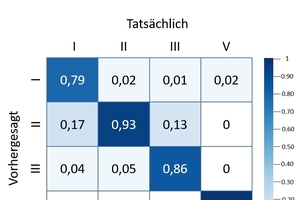

To assess the performance of the trained model, a confusion matrix (»Fig. 6) on the basis of the tests performed was calculated. These data can be used to obtain a differentiated evaluation of the performance of the classifier in the categorization of brick particles (»Table 1). The most important characteristic values that are calculated with the help of the confusion matrix are also briefly explained in »Table 1. The diagonal values in »Fig. 6 present the sorting rates for every category. It is notable that Category V (impurities) shows a near-perfect prediction, whereas Category I (dense-fired material) reaches the lowest sorting rate of 79 %.

»Table 1 contains a more detailed breakdown of the classification results for each category. Category V achieves a very good accuracy of 99.9 %, followed by Category I with 96.1 %. The accuracy values vary between the categories, with Category II showing the lowest accuracy with 83 %. In contrast Category II shows the highest sensitivity with 93.2 % whereas Category I with 79 % reports the lowest sensitivity. Overall, the F1 value for all classes is over 80 %, which indicates a robust performance for the classification and sorting of masonry particles.

Overall, it can be said that the classifier shown performs well. The misclassifications can be attributed to several factors, e.g. dirt on the belt conveyor or mechanical problems with the sorting flaps. An upgrade to a camera with higher resolution can contribute in future to improving the identification as with this the textures of the small objects show greater detail and differences are more clearly highlighted. The implementation of additional classifications can be considered for further optimization of the identification process.

4. Summary and outlook

Overall, the developed identification algorithms show very good results for the automated, sensor-assisted differentiation / sorting of different brick types. Especially with the regard to the identification of foreign particles (Category V) within the batches identification rates of 99.9 % were determined. Despite the complex challenge of distinguishing between single-variety, hard-fired material (Category I), high-fired, hard material (Category II) and low-fired, softer material (Category III), the classifier achieved recognition rates > 90 % for all categories and an F1 score of over 83 % for all material classes. This accuracy proves the robustness of the approach chosen, especially in a controlled laboratory environment.

In future, more influencing factors, like camera resolution, lighting, clinging dust and material moistures will be studied in more detail. Planned for this is to use a line camera with higher resolution and an expanded spectral range (near-infrared spectrum). Furthermore, the improvement of the machine learning algorithms can contribute to even better reactions to variations in the brick characteristics and environmental conditions. These improvements can pave the way for scaling of the technology to industrial applications and make them a valuable tool for sustainable industry processes and construction products.

The process currently developed and proven on laboratory scale must be upscaled step by step to a larger sorting system. For this, further tests are to be undertaken on the influence of process-influencing factors on the identification, and the findings implemented in the identification software. For this, companies that can implement new processes are needed. Realization in practice is possible and promising.

Acknowledgements

The IGF project no. 22068 BG with the full title: “Automated hyperspectral imaging and image analysis for the sorting of bricks and masonry rubble using machine learning methods” was funded by the Federal Ministry for Economic Affairs and Energy on the basis of a resolution of the German Bundestag.

![»Fig. 2: Water absorption as a function of the density for the samples used in different categories. Translation: Abscissa: Density on kiln-dry basis [g/cm3]; Ordinate: 24h water absorption [mass%]; Caption: Dense-fired bricks, clinker bricks (Category I); Clay blocks (Category III); Clay roofing tiles, facing bricks (Category II); Other (concrete, …) (Category V). Numbers in German format](https://www.zi-online.info/imgs/2/2/4/6/9/0/4/tok_07d67c3c733c956167b7aefe51eb7b3e/w300_h200_x600_y336_Abbildung_2-6fc89c2f418b0e0f.jpeg)

![»Fig. 5: Mean identification rate and standard deviation for the root categories – identification rates (sorting rates) achieved in practice with SVM.Translation: Below: Root categories, Total; Left: Identification rate [%]](https://www.zi-online.info/imgs/2/2/4/6/9/0/4/tok_1bc14b27de43bb22c9b9d22fdadff703/w300_h200_x447_y291_Abb._5_neu-6fd23534d087dccc.jpeg)