Quality improvement of ceramic products by raw material and mass testing

There are many reasons why an operating mass in a brick factory needs to be adjusted. At some point, even the largest clay deposit is exhausted or the properties of the clay in the pit have changed to such an extent that the properties of the bricks no longer meet the required specification for the manufacturing process or the product quality. Market conditions and changed requirements for the procurement of raw materials by suppliers may also make it interesting to adjust or replace the proportion of the respective raw materials.

Development of ceramic masses

For more than 60 years, the Keller Application Laboratory has been researching in the field of raw materials and has been using its analyses to support efficient production processes. These long years of experience in the development of ceramic masses is combined with the customer requirements and the legal specifications regarding climate protection. In this way, manufacturers are supported in their efforts to continue producing the “world‘s most beautiful” building material also in the future, says Keller HCW.

Thanks to the close cooperation and continuous exchange with plant managers, plant laboratories, raw material processors, investors and the KELLER engineering, the challenges of the available raw materials and the effects on existing process and plant technology are well known.

Different procedures

There are different procedures for the development of masses. If only one clay is to be replaced by a new clay, this is added to the other components of the mixture in specified proportions, after consultation with the customer. This new mixture is adapted with regard to plasticity and is extruded according to the customer’s specifications under practical conditions to form various test bodies. The properties of the new operating mass are tested on these test bodies and, if necessary, the proportions of the clay components are adjusted in a further mix.

If several clays are available for selection for a clay to be replaced, these clays are first examined individually. Hand test bodies are first produced to investigate the basic suitability of a clay material. In this way, a preselection can already be made depending on the requirements. For example, the formation of residual cores can be a criteria for exclusion. After having selected one or two clays, the clays are extruded individually under vacuum to form various test bodies in order to examine properties such as bending strength, compressive strength and fire resistance. Once these tests have determined the clay to be used, the composition of the new mixture is determined in further tests.

In case a new production plant is established or a new product is added to the product range, it is often necessary to develop a completely new clay mixture. For this, all possible raw materials are first examined separately in order to create a new mixture according to the desired properties.

If a mixture becomes more plastic due to a change in clay, it often has to be adjusted by adding leaning agents. In this case, raw material resources can also be saved by the addition of firing waste. The Keller application laboratory also provides support for this task, promises the company.

Optimize the operating mixtures

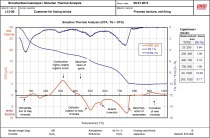

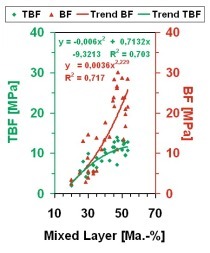

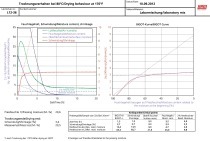

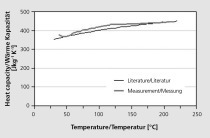

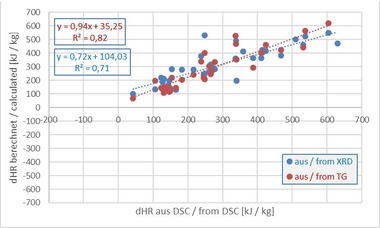

In addition to the examinations of the test bodies, the determination of the particle size distribution is also important for the development of the mass. Proven practical measurements are carried out to assess the drying behaviour in order to optimize the operating mixtures. The eluate analysis and the chemical analysis play an important role in the selection of raw materials. Here, the amount of water-soluble salts is determined, which may cause efflorescence on the fired products and corrosion in the plants. Thermal analyses (simultaneous thermal analysis, dilatometer measurement) serve to obtain additional information about the raw materials and mixtures, which is used, among other things, to optimize the firing curve for the new operating mass.

No matter which ceramic products are to be produced, the Keller Application Laboratory provides support in the development and adjustment of the operating masses, as well as in the professional taking of samples from new deposits, existing pits or from stockpiles, says Keller.