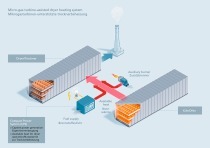

Use of biomass in the drying and firing of

clay-based building products

clay-based building products

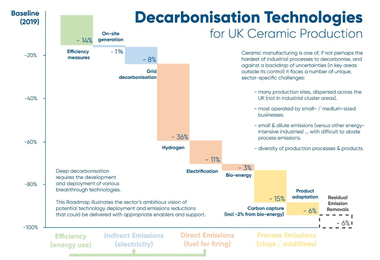

The brick and tile industry is obliged to reduce its CO2 emissions by at least 32% by 2025, as compared to 2005 levels.

Kilns and dryers, though, are already very efficient, and the remaining latitude for reducing CO2 emissions by further increasing process efficiency is very limited.

According to EU Directive 2018/410, biomass will continue to be regarded as a CO2-neutral fuel for at least the period of 2021 through 2030, so replacing natural gas with biomass is a quick way to dramatically reduce CO2 emissions. Implementation can be carried out in phases, beginning with the dryer.

Beralmar always adapts its combustion solutions to the available type of biomass as well as to local labour and environmental requirements. There are a number of potentially problematic aspects and issues that must be resolved, if gas is to be replaced with biomass. To be successful, such a conversion requires not only an experienced supplier and careful consideration of bespoke solutions, but also great determination on the part of brick and tile producers.

Miquel Moix, Beralmar Tecnologic S.A., Barcelona