Use of gas microturbines in the brick and tile industry

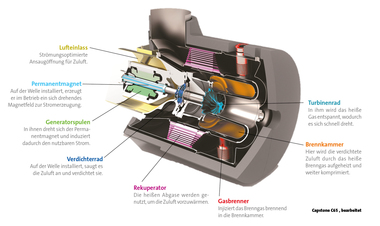

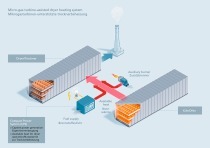

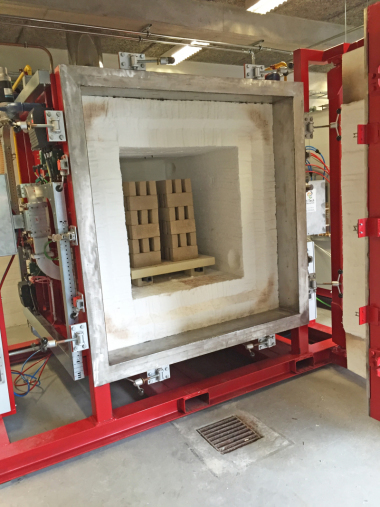

Gas microturbines have proven themselves dependable as combined heat and power generators in the brick and tile industry. Thanks to their technological specifics, they optimally cover a diverse range of applications, especially in connection with the direct use of exhaust gases.

The current contextual constraints of KWKG 2017 (latest version of Germany‘s Combined Heat and Power Act) and of EEG 2017 (German Renewable Energy Act as amended 2017) concerning captive power generation point to highly profitable plant concepts. The combination of long runtimes and an ample cost spread between gas and electricity as sources of energy yields short payback times both for brick plants without partial EEG exemption and for facilities that profit from the “special equitable adjustment provisions of the EEG“. For the latter group of enterprises, captive power generation is currently devoid of drawbacks regarding the determination of power cost intensity.

This report describes the current situation for the brick and tile industry.

Dipl.-Ing. Franz Obermeyer, Ingenieurbüro für Energieeffizienz und Umweltschutz