ZMB Braun’s collection reflects the evolution of die technology

For some time now, Friedrichshafen-based ZMB Braun GmbH has been hoarding a special kind of “treasure” in a simple storeroom: numerous extrusion pressure heads and more than 150 brickmaking dies that gradually accumulated over the years. Recently, in connection with Braun’s restructuration of their production process, the storeroom had to be cleared out. Its contents turned out to consist of some genuine collector›s items plus sundry test models, prototypes, returned articles (from insolvencies, for example) and so on.

Covering a time span from about 1895 to 2005, the hoard provides insights into 110 years of extrusion die evolution. Recognizing the high techno-historical value of the collection, Managing Director Gerhard Fischer asked former Händle hand Willi Bender and ZMB Braun staffers Dimitri Block and Vincenzo Albano to take stock of the collection and draw up a catalogue. For that, they enjoyed the welcome assistance of Chief Engineer Claus Homburger, whose expert knowledge was most helpful in connection with the “exotics”, including a vibrating die, an osmotic die and a hovering (air-cushion) die. The team also consulted Sebastian Haag, a Braun retiree who was with the company for 49 years. He was able to report that, for the first few years following Braun’s establishment in 1926, the company also made wooden extrusion dies. Back then, brickmakers brought their own wooden die frames to Braun, where they were fitted out with sheet-metal liners and the appropriate core inserts. A constant quest for new, more wear-resistant materials and ways to control the flow of material in a manner to ensure as uniform a column advance as possible – for pressure heads, too – runs like a red thread through all the decades of development since then.

The most interesting pieces of the collection are being put on display for ZMB Braun’s customers and other visitors. The company would even be glad to loan out a number of the dies to interested brickmaking museums or the like. There, the dies could be paired with the corresponding end products to show visitors how complex brick geometries are realized.

The progressive development of heavy clay products and die technology is never going to cease. Not for naught does ZMB Braun go by the motto “Form follows idea”.

Willi Bender

ZMB Braun GmbH

www.zmb-braun.de

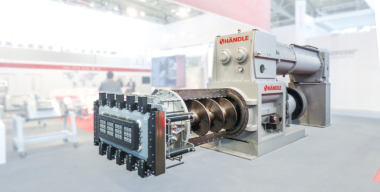

Händle GmbH Maschinen und Anlagenbau

www.haendle.com