ibea’s BT Master SC for quality control of clay pavers

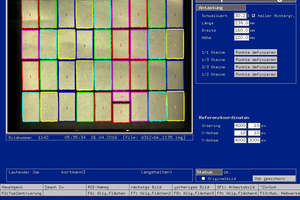

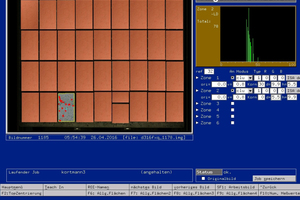

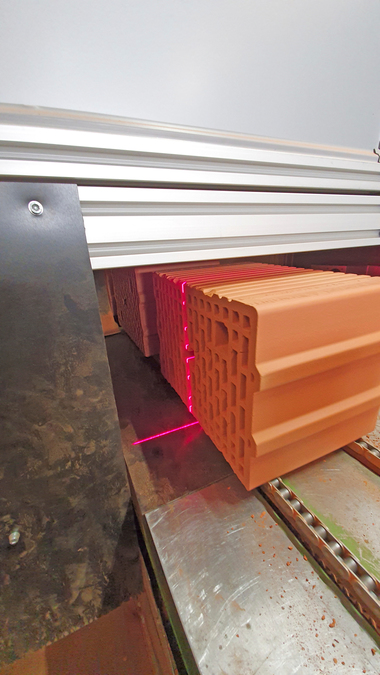

The BT Master SC (Brick & Tile Master for scanning and sorting), a new system from ibea, can be used for the quality control of clay pavers on a pallet. It uses a high-resolution colour-line camera to scan an image of the products to be checked and in this way determines its quality and position. The quality can be determined based on different defect criteria:

»Holes

»Corner breakage

»Dents

»Contamination

»Cracks

»Colour deviations

»Texture deviations

»Other anomalies

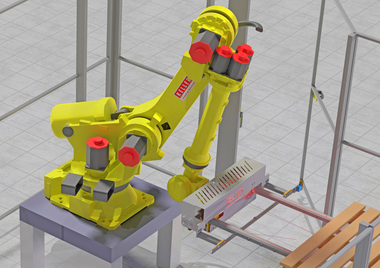

The information captured is transferred to a robot controller via a PLC, which controls the five-axis sorting robot. The faulty products are identified and sorted out. Here the robot also generates sample bricks that are issued separately for later documentation.

The extracted and sorted bricks are replaced with corresponding good bricks previously provided. The complete layer of a palette is sorted and re-sorted in 30 seconds, in case all bricks are changed, in max. four minutes. In the end a pallet is transported with 100 % OK bricks. The sorted NOK bricks end up in a breakage container. At the end, the system covers the individual layers, labels them and puts a corresponding identifier code on the side of the pallet with the same robot.

The robot is equipped with a vacuum gripper that includes a vacuum matrix so that the different sizes of the pavers and also e.g. two pavers next to each other can be gripped. Small product crumbs are vacuumed up by the gripper.

ibea Hamburg GmbH

www.ibea.de