News on heat flow and flow measurement in process air and flue gas with practical examples

For many years, the process air system in brick production was considered a ‘secondary process’ that received significantly less attention than the kiln or dryer system itself.

Rising energy costs and ambitious transformation targets in recent years have led to a much greater focus on the importance of process air. The flow rate (standard volume flow) and heat flow in the process air ducts play a central role in this:

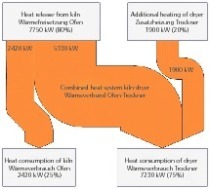

Optimisation of waste heat utilisation from the kiln for the drying process (in Austria in particular: reduction of CO2 certificate costs)

Optimisation of the drying process with regard to its highly humid exhaust air

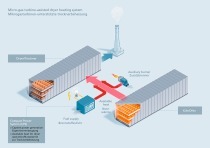

Waste heat utilisation from flue gas – also with regard to the waste heat register in accordance with the Energy Efficiency Act

For over 8 years, Luftmeister has specialised in supplying, installing and calibrating suitable measurement solutions for the roof tile and backing brick industry, and handing them over for use with a final signal test. This presentation provides an overview with interesting practical examples.