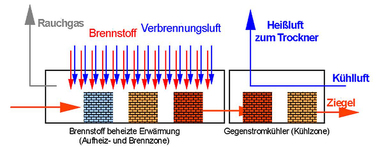

Possibilities and limitations of energy saving in tunnel kilns

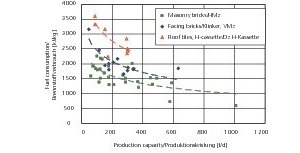

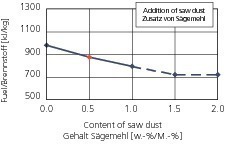

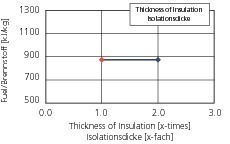

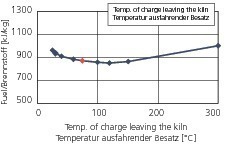

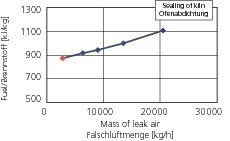

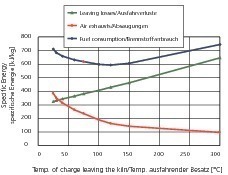

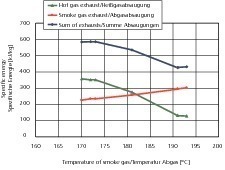

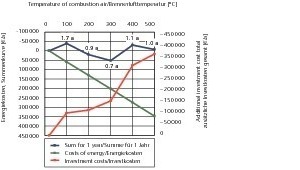

Over the past years energy saving and reduction of emissions have become more and more important in the brick industry, in particular with regard to the rising costs for energy and the trade in emission certificates. Thus plant manufacturers are currently concentrating their activities in the energetic optimization of the large-scale consumers of fossil fuels – the dryers and kilns. In this respect the potential for optimization is still far from having been exhausted. In addition, the continuous increase in energy costs will even lead to the realization of projects which previously have been rejected as economically less efficient. Simulating calculations are increasingly utilized in the design of new plants as well as for the optimization of existing dryers and kilns. The Lingl-developed software for tunnel kiln process simulations enables the detection of the customers‘ individual energetic saving potentials. Selected examples shall show that the success of the individual saving measures strongly depends on the conditions in the factory and that the measures result in varying amounts of potential savings. One of the examples was taken to compare the potential savings with the required investments and their profitability.

1 Introduction

The costs for energy and raw material are continuously rising and increase the operational costs of plants. This trend leads to a process of economical reconsideration. Current developments show that already...