Certified energy management according to international standard at all Röben plants in Germany

As one of the first com panies in the structural ceramics sector, Röben Tonbaustoffe GmbH now possesses the prestigious DIN EN ISO 50001 test certificate for all its German facilities.

Application of that international standard is geared to conserving energy, reducing greenhouse gas emissions and generally decreasing a company’s environmental footprint.

Röben’s energy management system has been introduced and successfully employed at all seven plants in Zetel, Querenstede, Bannberscheid, Brüggen and Reetz. It comprises energy economizing measures for the manufacture of facing bricks, brick slips and clinker veneer, roofing tiles and accessories, backing bricks, prefab elements and ceramic flooring.

About a year ago, Röben started aligning its production and administration at all German facilities with the requirements and stipulations of the aforementioned ISO standard. At all locations, project groups and energy officers/teams were formed for implementing the targeted measures. Overall responsibility for the energy management system lies with Managing Director Ralf Borrmann, who also heads the engineering and production division and now serves as the company‘s energy manager. “We have familiarized our employees at all the various plants with the energy management system”, Borrmann explains. “We have sensitized and trained them accordingly. As a result, we have progressed beyond simple day-to-day efforts to save energy and are now in a position to recognize and utilize new potentials for conserving energy.” These include, for example, the use of more efficient, more eco-friendly motors, the systematic use of hot kiln exhaust for other steps of production, and further improvements in quality for lower reject rates and, hence, lower energy consumption. The projects are analysed and appraised at yearly intervals, and every three years the progress made is crowned with a recertification audit.

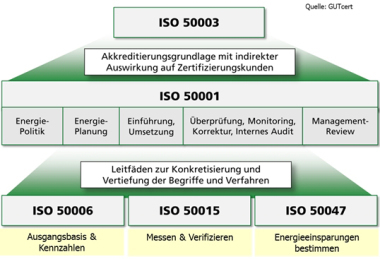

GUTcert, the Berlin-based management system certification company, performed Röben‘s certification, and Dr.-Ing. Volker Albrecht of EMC Berlin helped Röben get the EnMS established.