Reducing energy costs with clever energy management

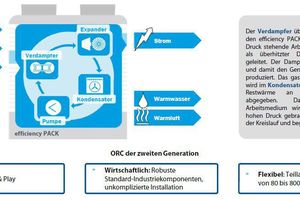

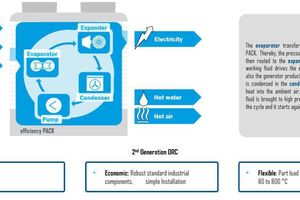

Energy efficiency measures are not only good for the climate; they help to save energy costs and are a suitable instrument for successful ISO 50001 certification. With the certification of the energy management system, industrial operators can prove that their company is managing its energy in a sensible way. Gottfried Tonwerke has succeeded in doing so with the construction of an ORC system for the recovery of exhaust gas energy at the rotary kiln in its clay plant.

1 Introduction

In order to remain competitive, companies have to operate successfully, save costs and invest at the same time. High energy costs resulting from energy-intensive production processes or from heating or lighting buildings are significant items on the company‘s balance sheet. Improving energy efficiency can offer great potential for savings.

In industry, energy often remains unused and is lost in the form of waste heat. This also affects energy-intensive sectors such as the brick and ceramics industry. Here, the high dust load of exhaust gases often gets in the way of using a...