Benefits and boundary conditions of fast firing clay

building products (Part 1)

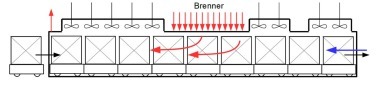

This contribution is the last of a series of articles dealing with kiln settings in terms of pressure drop, flow distribution, convective heat transfer and optimal configuration, as well as with the boundary conditions and benefits of fast firing kilns for clay building products [1-4]. Part 1 of this tripartite article describes the boundary conditions to which fast firing kilns are subject.

“… the further development of tunnel kilns for firing clay products has always been and still remains geared to fast firing as a long-term objective“ - Karsten Junge [13].

1 Introduction

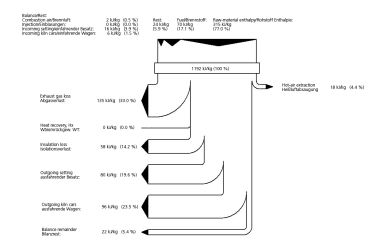

Clay bricks stand in increasingly stiff competition with other building materials. Due to factors like proprietary extraction and preparation of raw materials and the two-stage drying and firing process, their technology of production is comparatively cost-intensive, and the costs of investment and operation are accordingly high. The thermal energy expenditures alone presently account for some 25 to 35 % of the...

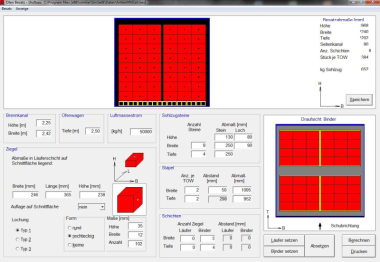

![»2 Velocities of flow around and through a model lattice setting (dotted area) in a flow channel (white area) acc. to [46]](https://www.zi-online.info/imgs/1/2/1/3/4/7/3/tok_486ed8541072a69998c60e0557a61177/w300_h200_x400_y282_Bild_2_800_565-5c453a96b601cf5c.jpg)

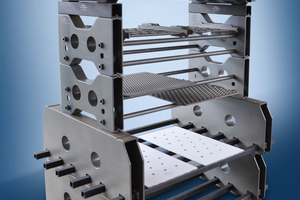

![»3 Stackable SiC drying supports for facing bricks [1, 4] (study performed for Lingl by Schunk Ingenieurkeramik)](https://www.zi-online.info/imgs/1/2/1/3/4/7/3/tok_37ccf242018bfb6ca9f78ef816d413c6/w300_h200_x297_y421_Bild_3_595_842-4e820302deb8d345.jpg)