Causes and avoidance of damage on account of diffusion-dependent reactions in the preheating zone of tunnel kilns

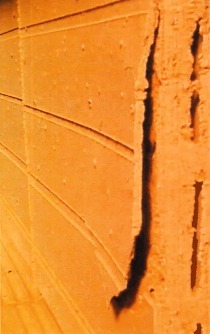

The likelihood of body damage and spalling being caused by thermal stress during the firing process is very high. Green brick strength is decisively dependent on water content. Brick raw materials with different mineral compositions develop different levels of tensile strength. Indeed, even minor body temperature gradients can cause damage to insufficiently dried green bricks during preheating. Bodies with a high level of texturing are most likely to sustain damage, while bodies with a low texture level survive the preheating process undamaged. Aiming for low residual water content in the drying of green bricks is the most expedient way to minimize the cause of damage, and reabsorption of moisture before the firing process begins should also be avoided.

1 Introduction

The firing of heavy clay products is subject to a number of such limiting factors as expansion and contraction processes, endothermic and exothermic reactions and the conversion and neoformation of mineral phases. These processes are rate-determining for the firing of any heavy clay product.

Considering the diversity of raw materials employed for the brick and tile industry’s broad range of products and how they differ in terms of mineral composition, chemical composition and particle size distribution, the firing process must be adjusted to the respective raw-materials situation in order to accommodate the relevant dependent reactions. For greenware of the type normally fired in tunnel kiln settings, the firing process (heating and cooling rates and ultimate firing temperature) is defined by the product firing curve. During heatup, temperature gradients arise between the surface and the core. Their magnitude is primarily dependent on the heating rate and on the geometry of the products. Major differences in temperature give rise to internal stress that can cause cracking and/or structural damage. Due to the parabolic temperature profiles within the green bricks, the steepest temperature gradients are situated near the surface. As such, there is particularly great danger of near-surface cracking due to thermal and material-dependent expansion and contraction processes. In addition, the likelihood of cracking may also be heightened by shaping errors in the form of microstructural weaknesses and textures.