Digital printing –

opportunities and challenges in heavy clay ceramics

More than 30 years ago, the first digital printing systems were available for use in the graphic arts industry. In ceramics, the first digital printing system was put into operation in a tile factory in Spain in 2000. In tile production, 80% of the entire industry worldwide switched from screen and rotary printing to digital printing within a period of ten years. Today, digital printing is established and most of the problems that initially made handling difficult have been solved.

1 Mode of operation of digital printers in ceramics

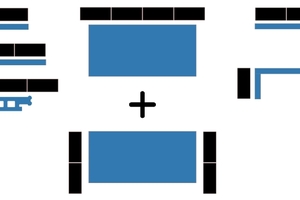

All ceramic printers are based on a similar functional principle, that is “Drop-on-Demand“ (DoD). This means that a piezo-controlled printhead ejects the corresponding amount of ink as required. The print is always made contactless onto the surface to be decorated – from a distance of 3 to 9 mm, depending on the depth of focus.

The printheads are integrated in an ink circuit (»2) consisting of heating elements, pumps and filters. In respect of hardware, this circuit is responsible for the printing result. Depending on the printer and the...