Heat pump technology for industrial processes in the high temperature range

Waste heat utilization by means of heat pumps

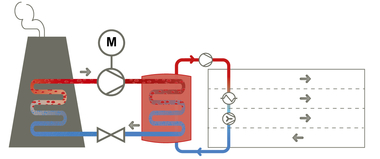

Waste heat from industrial processes has so far mostly been released unused into the environment. Within the framework of the EU project DryFiciency, this specific heat pump technology has been developed over the last three years under the leadership of the Austrian Institute of Technology (AIT) and a demonstrator has been integrated into the drying process.

The DryFiciency development project sets a milestone in the direction of decarbonization in the brick industry and is a prime example of how innovations from research can be quickly brought to market. DryFiciency shows that heat pump technology can also be used for industrial processes in the high temperature range.

The overall objective of the DryFiciency project is to develop technically and economically viable solutions for reducing primary energy demand and CO2 emissions by recovering energy from waste heat streams.

Demo project for tunnel dryers

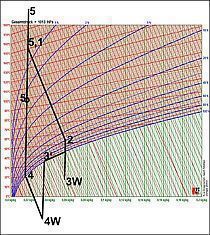

At the Uttendorf plant, the new heat pump heats a section of the tunnel dryer. In the first four weeks after commissioning, it was possible to operate in all the temperature ranges envisaged, up to the targeted maximum temperature of 160 °C.

In the course of the DryFiciency project, two industrial high-temperature heat pump systems for waste heat utilization are being developed.

They have the potential to save up to 80% of the energy consumption and the corresponding CO2 emissions in industrial drying processes and thus significantly reduce production costs.

Outlook

A second high-temperature heat pump from the DryFiciency project is being used by consortium partner Agrana. Compared to the Wienerberger heat pump, which works with piston compressors, the heat pump at Agrana is implemented with screw compressors. This configuration is more efficient when a large operating range is covered. It also offers advantages in terms of start-up behaviour and approval due to the lower refrigerant charge per circuit.

A second high-temperature compression heat pump will start operation at another Wienerberger site during the next two years and will then be measured for roughly two years.

The Austrian Institute of Technology continuously publishes technical findings (http://dry-f.eu/).

www.wienerberger.at

www.ait.ac.at