Influence of circulation systems in tunnel kilns on heat transfer and energy consumption

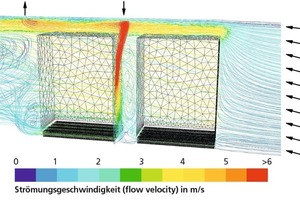

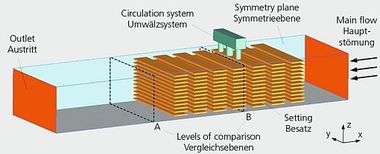

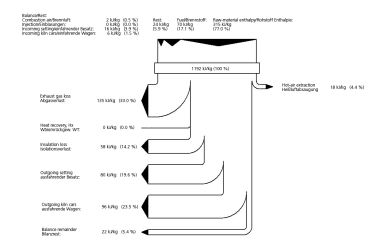

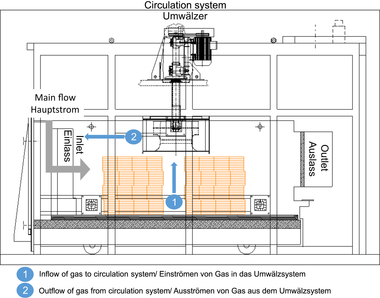

If the tunnel kiln is simplified as a countercurrent heat exchanger, it can be mathematically shown that the enhancement of the heat transfer between atmosphere and solid reduces the energy consumption. This can be explained with a lower temperature difference between the two flows and therefore a reduction of exit energy losses. In addition to the axial flow, circulation systems acting in the cross-section can increase the effective flow velocity and thus the convective heat transfer. Beside the convection, the heat transfer is mainly influenced by radiation and the conduction within the setting itself. Circulation systems are more effective when they are used in the low-temperature region of the tunnel (up to 500° C) and when a looser setting is used with gap widths of about 20 mm. The arrangement of circulation systems in the tunnel is investigated with computational fluid dynamics (CFD). Some recommendations will be given for an optimized flow of typical products such as roof tiles and bricks.

M.Sc. Tino Redemann,

Otto-von-Guericke-Universität Magdeburg