New preparation and shaping line for Yamama Company

for Red Bricks & Clay Products Co. Ltd.

Being a customer of Bongioanni Macchine since 2011 (when the roofing tile production line was installed), Yamama Company has continued to place its trust in Bongioanni’s technical/commercial staff, thus enhancing an already strong business partnership that has then resulted in the realization of a new key project. The study of this new project has led to the realization of a brand-new plant for the production of 250 000 t/a fired clay bricks, located in the new industrial area of Niisah, just outside of Riyadh, about 60 km from Yamama’s headquarters

In October 2012, the Yamama Company once again selected Bongioanni Macchine. The Italian machine engineering company received an order to supply the preparation, storage and production lines, up to the extruder, for its new production plant. The two companies signed a contract for the implementation of this project. Then in 2013, owing to numerous adversities, Yamama Company was forced to put its plans for the realization of the new clay brick production plant on hold – the plant was finally completed in the second half of 2017. As a result of these unexpected circumstances, Bongioanni Macchine had to postpone the delivery of the machines until 2016, thus delaying also the installation works until the end of 2017.

In March 2018 the new preparation line of the plant was started up and at the end of April 2018 the production capacity required by Yamama Company for the production line and the storage silo was finally achieved, thus leading at the beginning of May 2018 to the successful start-up of the production line.

At present, the plant operates 50 weeks/year in 12 shifts/week, of 10 hours each (8 net hours).

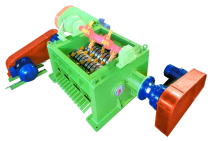

The preparation line supplied and installed by Bongioanni Macchine consists of:

two automatic box feeders

one rubber belt box feeder for sand

one R1200/B clay crusher

one 13LD clay disintegrator

one Compact LS-810 primary roller mill

two box feeders (1000 x 4000 mm) for the refining roller mills

two Compact LS-810 refining roller mills

one Mix710D filter mixer

one Mix710I double-shaft mixer

one dedusting installation above the disintegrator and the three roller mills

After the preparation process, the clay is stored inside a 4-storage-chamber silo and then it is dug and collected by a 50EM1422 excavator, to be conveyed to the box feeder of the production line. The production line consists of:

one box feeder

one high-speed Compact LS-1012 refining roller mill

one Mix710D filter mixer

one Tecno 750 extruder

a dedusting installation for the roller mill

The extruder is equipped with an RV-79/AFP automatic moisture control device. In addition, an RV-79/AFP hydraulic lifting device was installed to adjust the extrusion heights to the different products.

Moreover, Bongioanni Stampi has also supplied two pressure heads with braking system on all four sides and tailored Gamma Plus extrusion dies for shaping of the following main products:

one 2-exit Gamma Plus extrusion die for the production of bricks for load-bearing walls (Ref. YN-204 [400 x 200 mm])

one 4-exit Gamma Plus extrusion die for bricks for partitioning walls (Ref. YM-401-A [200 x 200 mm])

one 2-exit Gamma Plus die for ceiling blocks (Ref. YH-306-A [400 x 240 mm])

YM306, YM401-4-4 and YN204 bricks

All these extrusion dies are equipped with cores and frame made of BSC01 alumina, with a hardness of 1750 HV, and with a high-thickness chromium plating both on the bridge – which is made of anti-abrasion steel – and on the under-frame plate.

The Tecno 750 extrusion unit is then completed by the pressure heads with differentiated slope that have been custom-designed. These are made of anti-abrasion steel (thickness 15 mm) and are fitted with an externally adjustable braking system, allowing control of the flow of the clay fed to the extrusion die.

In addition, Yamama Company has been supplied with a complete set of first-need spare parts for all the machines supplied by Bongioanni Macchine, to ensure operation for at least one year.

Bongioanni Macchine S.p.A.

www.bongioannimacchine.it