“Old, but not outdated“ – at 120 fit for the digital future

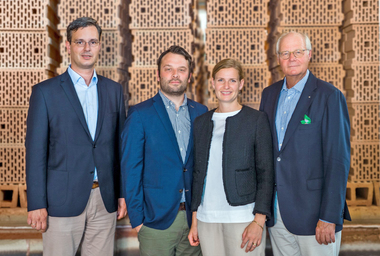

In 2019, the August Lücking clay brickworks and concrete plant in Warburg-Bonenburg celebrated its 120th anniversary. In the anniversary year, Managing Partner Joachim Thater passed on responsibility to the next generation. His daughter Theresa Lemke, Managing Partner, together with her husband Richard Lemke, authorized signatory, is leading the company into the future – and the future is becoming increasingly digital.

1 An industry in transition

If you ask the two young company managers why they chose this very traditional industry, their answer is not so different.

Theresa Lemke grew up with the brickworks as the daughter of a brickworks entrepreneur and has been influenced by the history of the Thater family, which had many and diverse ties to the industry. The 29-year-old now represents the fifth generation to take over the management of the company, with responsibility for the entire company, its shareholders and its predominantly long-serving employees. Together with her husband Richard Lemke, she quickly decided that this would require exploring new avenues. The first projects have already been initiated and are now being realized.

Richard Lemke, who took his first entrepreneurial steps at the age of 15, is himself an active entrepreneur with a holding company that brings together six start-ups in the digital sector. Growing up in the Oldenburg region in a family with a tradition in the legal profession for generations, Richard Lemke had encountered an annular kiln brickworks as a child. In expectation of an artisan-dominated production, he was completely surprised by the industrial orientation of the production of backing bricks and prefabricated concrete elements at Lücking during his first visit to Bonenburg. He is now all the more excited to actively participate in shaping the challenge for the digital future of the company with his background and network.

He sees exciting prospects for the company, as the building materials industry is undergoing radical change and confronted with new challenges. This also includes the population’s increasing climate awareness. The environment and climate protection have been one of Lücking’s focuses for years. In 2019, with an investment volume of € 1.5 mill., E.I.Tec. redesigned the exhaust gas cleaning with the installation of a regenerative thermal post-combustion oxidizer with a heat exchanger and a waste heat boiler for hot steam generation. For Lemke, it was quite surprising how investment-intensive a brickworks is in order to be able to operate at the state of the art – in comparison with the digital industry from which he comes. Here a product, for example a software package, is developed once and can then be sold many times over with a click of the mouse. But Lemke is also astonished by the complex brick manufacturing process, with its energy-intensive costs in relation to the unit revenue.

As Lücking is active in both the brick and concrete sectors, a direct comparison between the two building materials is possible, explains Theresa Lemke, emphasizing that the differences in the manufacture of the products are considerable, although the revenues is almost the same. For the young managing directors, an optimization of processes and more effective data collection and utilization mean a way to save costs.

Compared to the IT world, the building materials industry often operates over very long periods of time. Richard Lemke: “If you don‘t develop and decide fast enough in IT, you‘re out!” In the brick and tile industry, decisions often take much longer; approvals or even building permits sometimes drag on for years, so that decisions are made without it being possible to fully assess their effects.

But the young entrepreneurs at Lücking do not want to wait and see how digitalization in the brick and tile industry will develop.

2 Digitalization in the brick and tile industry

The topic of digitization runs like a red thread through various areas of the company. Richard Lemke defines focal points, some of which are being worked on simultaneously. These include the introduction of a new ERP system, the networking of production, Building Information Modelling (BIM) and the development of a service platform.

> Optimizing ERP interfaces

The introduction of a new material management system was one of the most important challenges after the couple took over the management. The use of such systems has been standard for many years, but the technical possibilities have changed. In the past, often only accounting and purchasing were handled by ERP systems, but today all business processes can be represented and form the basis for extensive analyses.

As an IT specialist, Richard Lemke decided to develop in-house a special application for brickworks on the basis of standard software. Two new employees were hired for this purpose. As soon as the new system is fully implemented, planned for the beginning of 2020, it will serve as a basis for further optimization.

The aim of the investments is to make well-founded decisions on the basis of the data obtained and to significantly simplify communication with the trade. At present, it is still not unusual for a building contractor to order by fax. A lot is expected from the digitalization and optimization of this ordering process. This also includes avoiding incorrect deliveries and reducing telephone communication.

> Networking production

Especially in times of an increasing shortage of skilled workers, it is important not to rely solely on the experience of long-serving employees. The creation of a digital twin of the production operation helps to keep track of machines and systems from different manufacturers. With linking of the equipment, the entire process is mapped in one tool. As a result, among other things, faster reaction times in case of malfunctions, more effective maintenance and spare parts supply are expected. There are many optimization approaches. One example is vibration measurement in the preparation equipment. Here the degree of wear and tear and the time for necessary maintenance work can be predicted from the digitally recorded data.

As with the ERP system, the subject of data security is also fundamental in production. Therefore, the first step is to create the technical standards to be able to transmit data securely.

> BIM

BIM is a topic that concerns the entire construction industry, from product manufacture to installation. Another project topic is how to become involved as a manufacturer of building materials and be well positioned to transmit information digitally to architects and construction companies.

> Service platform

In response to the question “What service can I offer customers so that they can carry out their work on the construction site even more efficiently?”, new ideas are constantly being taken up and worked on in projects. For example, it is determined which data can be made available to the architect. This includes calculating the quantity of bricks for a project.

3 Being strong together as the clay brick and tile industry

The clay brick and tile industry in Germany is largely characterized by medium-sized companies. Keeping up with digitalization and employing the right people in your own company has become impossible for many smaller companies. In principle, the standards are the same and everyone has to deal with the same problems. However, the ERP software solutions available on the market seldom fit perfectly into brickworks. Richard Lemke decided that a solution that would really function well must look different. So, they programmed a solution themselves and took the needs of their own plants as the basis for development.

This software is now also offered to other brickworks, it is already being used by the colleagues from “Mein Ziegelhaus“, other brickworks can also buy it. Interested brickworks can thus acquire an ERP system suitable and optimized for the industry and bring it to life with their data. Of course, the data sovereignty lies with each individual brickworks itself, Lemke emphasizes: “We only develop the software!”

4 Prefabrication in the brick sector will come

The management is convinced of this. As Lücking already has many years of experience in the prefabrication of concrete elements and senior boss Jochen Thater knows prefabricated brick elements well from the past, it was obvious to take this route in the brickworks, too. “The production of brick elements is nothing new“, emphasizes Jochen Thater, “it has been around for 50 years.” Now, however, the time is ripe and there is an opportunity for brick as a mass product, also in view of the trend towards higher storey buildings being built with bricks.

The company has therefore invested in a semi-automatic plant for the production of brick elements from Lücking high-precision brick units. With the help of the semi-automatic machine, a brick wall, including the necessary recesses for windows etc., can be produced in the production facility and then – like the precast concrete elements from Lücking – delivered to the building site. Thus, the contractor can realize more construction sites with less personnel in less time. For the medium-sized company Lücking, the new brick element plant means increasing its value creation. Owing to the interaction of brick element and precast concrete elements, such as ceilings and stairs, it is possible to install a complete house, the “Lücking building package“ in a short time.

Apart from the increasing lack of skilled workers, this also offers the possibility to produce the elements independent of the weather. First of all, it is important to gain experience with the new system and to convince the building contractors of its value. Together with the building contractors, it is necessary to define what is expedient and necessary.

The Lemkes agree: “We assume that modular construction will become more and more established.” Prefabrication makes sense when everything goes hand in hand, from planning to brick and element production to the construction of the building. The systems used by the architects or building contractors are also important. At Lücking, they aim to use a system that can use all data. They are already working on such a system.

5 Conclusion: Not only keeping an eye on the technology

The young entrepreneur couple, Theresa and Richard Lemke, have brought a breath of fresh air to the traditional brickworks. Their aim is to bring brick, a building material that is thousands of years old, into the digital age. For both of them, the focus is not only on the technology, the processes around it and the interfaces must fit, too.

Anett Hümmer

August Lücking GmbH & Co. KG

www.luecking.de