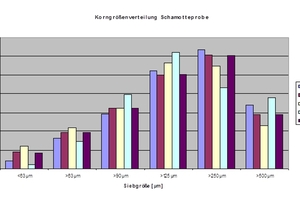

Sampling as the basis of meaningful raw- and processing material analysis

Sampling, beginning with proper documentation of the requisite data and selection of the appropriate means and standards, often evolves into a laborious and, frequently enough, expensive part of the inspection agenda for incoming goods, semi-finished products and the end-of-line acceptance process. Available template documents in the form of standards, regulations and directives are of limited scope. Nevertheless, various methods and tools, often quite simple, can be used for developing appropriate standards and specifications that enable representative sampling in many different areas. Whatever the case, it is always worthwhile to prepare for and implement optimal sampling in accordance with own, specific specifications (or with those described in the lecture). After all, what good are measured data gleaned from elaborate testing, if you cannot be sure that they are both reproducible and substantive? Also, with regard to potential complaints, the employed sampling procedures should be laid down in pertinent specifications and contractually agreed between customer and supplier as constituent parts of both the test schedule and the QA agreement between customer and supplier. Good sampling is an indispensable prerequisite for well-functioning, reliable in-plant quality control – and it helps prevent unpleasant surprises.

Dipl.-Ing. (FH) Stefan Link, Forschungsinstitut für Anorganische Werkstoffe – Glas/Keramik-GmbH