Decarbonisation through gradual electrification of thermal processes in brickworks

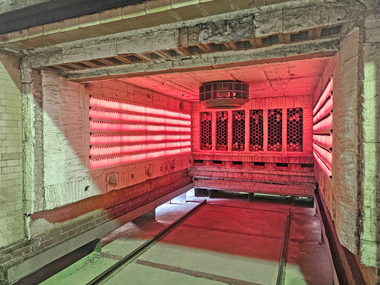

The industrial use of electric tunnel kilns has matured from pilot to demonstration scale. However, the considerable investment required for a complete conversion is a deterrent. In addition, high connection capacities and storage solutions are required on the grid side.

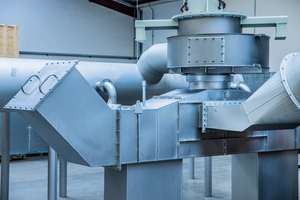

A combination of hybrid or fully electric tunnel kilns, heat recovery, heat pumps and digital optimisation of the energy sources used sets the technological cornerstones on the path to a climate-neutral brickworks during the transition period.

The presentation shows how existing plants can first be optimised and then defossilised in individual steps. It will address both the individual brick product groups and the limitations of such ‘small solutions’.