Development and demonstration of a hybrid kiln for brick production

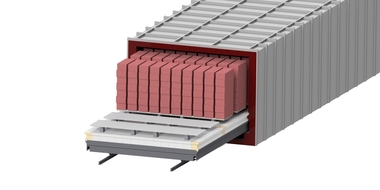

The bogie hearth kiln (test kilns) at IZF is being retrofitted with electric heating elements (230 kW) on both sides, in addition to the six natural gas burners, each with an output of 180 kW. The bogie hearth kiln can simulate flow conditions similar to those in a section of a tunnel kiln.

In addition to natural gas, electricity is also used as an energy source for the bogie hearth kiln to heat backing bricks to a temperature of up to 900 °C. By replacing or reducing natural gas and using pure electricity, the water and CO2 concentration in the kiln atmosphere is reduced or eliminated. This reduces or eliminates the radiant heat transfer coefficient between the kiln atmosphere and the backing bricks. This means that the kiln atmosphere would require a high temperature to compensate for the effect of the reduction in water and CO2 concentration. To overcome this decrease in the overall heat transfer coefficient, a high-temperature circulation system is installed in the kiln atmosphere. It can handle temperatures of up to 900 °C and increase convective heat transfer between the kiln atmosphere and the backing bricks. In addition to increasing the heat transfer coefficient, it improves the temperature homogeneity of the furnace atmosphere and the backing bricks.

This project is part of the eLITHE (Electrification of High-Temperature Heating Systems in the Ceramic Industry) research project within the framework of Horizon Europe.