The electric double-track kiln from ONEJOON

With the electrically heated industrial kiln at the Helpfau-Uttendorf brickworks in Austria, Wienerberger has created a very special piece of equipment. Apart from its electrically generated ‘firing’, its design and execution distinguish it as a high-efficiency kiln. ZI spoke to the developers at the Korean-German company ONEJOON about this technical milestone. In the following report, you can learn more about its development, the collaboration with Wienerberger and the history of the company.

How Wienerberger and ONEJOON came together

The collaboration between Wienerberger and ONEJOON at the Uttendorf plant is based on a joint project carried out several years ago. This led to an exchange of ideas about the possibilities of firing building ceramics electrically. ONEJOON already had extensive experience with the electric heating of ceramic goods. Wienerberger, on the other hand, wanted to examine the extent to which it is possible to fire relatively large ceramic bodies such as backing bricks on an industrial scale. This led to ONEJOON being commissioned as part of the Green Brick project (see ZI 4/25, p. 16f.).

The advantages of electric heating of ceramic firing goods compared to hydrogen

ONEJOON is currently focusing its technical development efforts on the supply of electrical energy for heating the plant. According to the company, this is based on the conviction that the future of industrial high-temperature heat generation will be electric. That is why the company is moving further and further away from gas-fired plants. Calculations have shown that, from an energy perspective, the efficiency losses involved in converting water to hydrogen fuel are too high for hydrogen to be a viable heat energy source in economic and ecological terms.

While the conversion of electrical energy into heat in the kiln using resistance heating has an efficiency of 95 to 98 per cent, the cumulative efficiency of hydrogen combustion for heat generation is significantly lower.

Under existing technical conditions, the production of hydrogen by electrolysis can achieve an efficiency of 70 per cent at best. In addition, the combustion efficiency is a maximum of 70 to 80 per cent. The overall efficiency is therefore only around 50 per cent. Other efficiency-reducing factors, such as the energy costs for transport, have not yet been taken into account. Taking all factors into account, ONEJOON‘s calculations show that electric firing is around 1:5 in terms of price and efficiency compared to hydrogen.

Development of the kiln

During the two-year development of the kiln, ONEJOON designed various concepts and models and ran simulations. The data obtained in this way was supplemented and validated by results from practical tests carried out on a 1:1 model at the ONEJOON site in Poland.

During development, ONEJOON employees had to overcome a number of technical hurdles. The interaction between the kiln atmosphere and the electric heating elements presented a challenge. To prevent corrosion of the heating elements, their design was improved and they were protected. This included, among other things, coating the elements with silicon carbide.

Two other areas of concern were the stability of the charge and the temperature distribution within the charge. This was solved, among other things, by adjusting the charge configuration and using convective air circulation. Another difficulty in developing the kiln was the tightness of the unit. To this end, the kiln body was redesigned and equipped with double locks to minimise the loss of warm gases.

How the kiln works

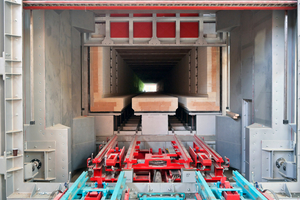

The kiln unit at the Helpfau-Uttendorf plant is a high-efficiency kiln with electric heating. In addition to tightness, the focus was particularly on improving thermal insulation and reducing extraction losses and heating costs by reducing the mass of combustion aids and kiln cars.

The use of alternative conveyor technology, namely double-track transport, was central to this, which in turn enabled the development of a more efficient kiln car and load design. The emphasis was on saving mass and optimising the flow cross-section. In this transport concept, two pairs of rails are located under the base plate, on which two very small and slim tunnel kiln cars on wheels stand. These cars in turn carry supports that protrude into the kiln chamber through slots. Movement therefore takes place under the kiln chamber. Only the supports are located in the kiln chamber. The fired goods rest on silicon carbide beams, which rest on the supports. The lower kiln chamber, where the double-track trolley with wheels is stored, is open but sealed off from the kiln itself with a special, newly developed insulation. This is to prevent heat accumulation in the transport mechanism chamber. ONEJOON does not wish to disclose details about the design, sealing and how air currents are handled in this area.

Apart from the transport system, the design of a double-track kiln is similar to that of a tunnel kiln. Thanks to the transport system, only a much smaller mass is required to transport the material to be fired. This reduces export losses to a minimum compared to a classic tunnel kiln.

Heating

Each heating zone contains electric heating elements or resistance heaters, which are well protected and installed in the heating zones. This allows the bricks to be heated in a controlled manner to a maximum temperature of approx. 1000 °C. The heating elements are coated with SiC to protect them from the kiln atmosphere.

Adaptation of the firing process

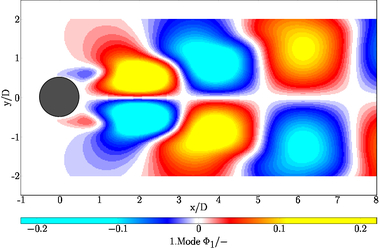

During the planning of the kiln, simulation studies were carried out to investigate the energy coupling of the heating elements into the kiln atmosphere and the product load. These findings were incorporated into the design process. Compared to a conventional gas tunnel kiln, significantly lower amounts of air and gas are available here, which greatly influences convection.

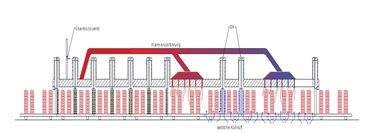

Air flow

The air flow in the kiln follows the classic counterflow principle: cool air is fed into the kiln chamber at the kiln outlet and conveyed towards the kiln inlet. It heats up as it flows through the bricks. In the heating zones, the thermal energy of the forced air is used to support the heating of the bricks. The forced air is extracted by a flue gas fan.

Temperature distribution

There is no active, forced convection in the traditional sense in the ONEJOON electric kiln. Instead, special air injectors are used. These are located in the heat radiation zones, i.e. where the firing takes place by means of electric heating elements. Injectors are installed in each zone to inject and swirl the air. This creates turbulence and, as a result, evens out the kiln air. This improves heat transfer in the radiation areas and helps to achieve temperature homogeneity.

ONEJOON opted for this form of air movement in the kiln for cost reasons. According to the kiln manufacturer, classic technical methods of circulation using heat-resistant fans are significantly more complex.

However, locating the injectors required some effort, as ONEJOON reports. Simulations and tests were carried out over a longer period of time. The company does not wish to disclose any details.

Removal of smouldering gases from porosity

As in a conventional tunnel kiln, smouldering gases are directed towards the kiln entrance by the thrust air. There they are extracted as far as possible to prevent condensation. Most of the exothermic reaction energy is used for heating, as in a conventional plant. The flue gases are then discharged via the roof or through afterburning.

Knowledge of air flow and targeted delivery to the right place, how we couple energy in and out – this knowledge is exclusive and the result of a process that has taken many years.

Energy consumption

According to the company, the energy consumption of the electric double-track kiln is around 30 per cent of the energy consumption of a classic, energy-optimised tunnel kiln, assuming the same production parameters. Compared to even more inefficient tunnel kilns, the ONEJOON kiln performs correspondingly better.

This also takes into account the energy used for porosity agents. Their calorific value is comparatively low at the Uttendorf site because only wood is used as a porosity agent there instead of lignite, hard coal or polystyrene. If classic porosity agents were used, energy consumption would probably be even lower.

The new one is more sensitive than the old ones

The ONEJOON kiln has a special operating feature that distinguishes it from conventional tunnel kilns: it is more ‘sensitive’ and reacts much faster to changes. The reason for this is that the ONEJOON kiln operates with very low air masses. There is no natural gas or other fuel gas and no combustion air. Only purge air is available and is used as sparingly as possible.

In comparison, much larger volume flows and quantities of air are moved in a conventional tunnel kiln. These systems therefore tend to react sluggishly to changes. With thousands of cubic metres of air being pushed through the kiln, changes in kiln operation can only be implemented slowly but in a controlled manner.

In comparison, the ONEJOON unit is not quite as easy to handle. Changes to the parameters had a much more rapid and pronounced effect.

The company ONEJOON, formerly Eisenmann Thermal Solutions

ONEJOON is a global industrial furnace manufacturer with over 125 years of experience and well over 1,000 systems delivered to date. The company‘s furnace systems cover a temperature range from 100 to 3000 °C and are used for the thermal treatment of numerous materials. These include the tempering of blade and saw bands, the sintering of metals and ceramics, and the production of cathode and anode materials for lithium-ion batteries. ONEJOON is the global market leader in the field of carbon fibre production equipment. The company is not only a furnace supplier, but also supports customers in the area of process development. Tests on heat treatment processes are carried out on behalf of customers in two test centres. The ONEJOON L2P programme (‘Lab to production’) enables these to be scaled up from laboratory to industrial scale.

ONEJOON has nine locations in six countries worldwide:

Korea: Headquarters in Suwon and production in Hwaseong (ONEJOON Ltd, Co.)

Germany: Bovenden and Böblingen (ONEJOON GmbH, formerly Eisenmann Thermal Solutions GmbH & Co. KG)

China: Shanghai and Haining (ONEJOON Zhejiang Co., Ltd.)

USA: Atlanta (ONEJOON Inc.)

Canada: Montreal (ONEJOON Thermal and Powder Process Solutions Inc.)

Poland: Gliwice (ONEJOON Poland sp. z o.o.)

The company employs a total of almost 400 people. Around 180 of them work at the two German locations alone. ONEJOON can look back on more than 125 years of experience in industrial furnace construction. This began with the invention of the first resistance-heated high-temperature furnace with temperatures of up to 3000 °C by the Ruhstrat brothers in 1896. The Ruhstrat company worked with the Böblingen-based Eisenmann Group in the field of carbon fibre plants from 2008 onwards. In 2011, Eisenmann AG acquired Ruhstrat GmbH. Later, the collaboration gave rise to Eisenmann Thermal Solutions GmbH & Co. KG, which brought together the furnace construction expertise of both companies. In order to further expand its presence in the Asian market, ETS began cooperating with the Korean machine manufacturer ONEJOON Co., Ltd. in 2016. In 2019, the two companies founded a joint venture in China. In the same year, the Eisenmann Group ran into financial difficulties – ONEJOON then took over ETS. In 2020, the company was renamed ONEJOON GmbH. The US site also opened in the same year. In 2021, the production site in Poland went into operation. In 2022, the company celebrated over 125 years of experience in industrial construction at its German headquarters in Bovenden.