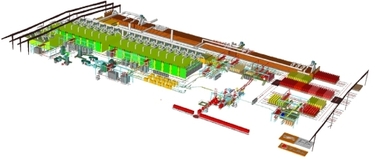

Turn-key roofing tile plant for Uralita starts production exactly on time

Lusoceram near Torres Vedras, 50 kilometres to the north of the Portuguese capital Lisbon counts among the more than 40 plants of the Spanish construction material group Grupo Uralita. This group is listed on the stock exchange and operates production facilities in 11 countries in Europe. Uralita takes a leading position in the markets of Spain and Portugal. Moreover, the group is considered to be the third largest producer of insulating material in Europe.

The Lusoceram location consisted originally of a plant for the production of roofing tiles and a plant for the production of bricks. As the main focus was to be laid on the production of new types of roofing tile, the brick plant was dismantled and an order was placed with Lingl for the new construction of a second state-of-the-art roofing tile plant.

Uralita relied on the know-how and experience of Lingl as an internationally recognized partner of the brick industry. The company located at Krumbach in Southern Germany is responsible at Lusoceram for a turn-key plant, including all foundations, with the complete equipment starting after shaping up to the packaging of packs ready for dispatch.

Lingl would like to emphasize the high level of cooperation throughout the entire project between the Uralita/Lusoceram team and the Lingl staff, working together as one team with one target. This was certainly one of the key points for success.

Technologically a special performance as some partial areas of the machinery would not have been able to meet the requirements of Lusoceram with their current design. Lingl developed and patented a new technical solution for the transport of H-cassettes which can be used on either side depending on the roofing tile type. This equipment was integrated in the conveying line and prevents the cassettes from being damaged, is characterized by a high performance and serves moreover for cleaning the cassettes from residual particles lying around.

Organizationally a special performance as Lingl ensured an unobstructed cooperation in every construction stage, also by integrating local suppliers in Portugal. Another profit for the customer were the lower costs resulting from this cooperation as no transport costs and customs duties incurred for the external services of the local companies.

Economically a special performance as Lingl handed over the new roofing tile plant of Lusoceram to the production team exactly on time and ready for operation – in spite of a very tight schedule. In March 2008 the order was placed and in spring 2009 the first roofing tile left the kiln. Then, together with the responsible staff of the plant, Lingl increased production step by step so that the planned target figure of 20 million roofing tiles per year at full capacity will be reached. New roofing tile types of first quality combined with all kinds of engobe and glaze variations are produced in the new plant at Outeiro da Cabeça in Portugal.