Concepts for reducing exhaust air loss from dryers in the brick and tile industry

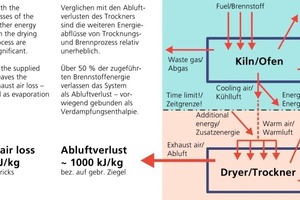

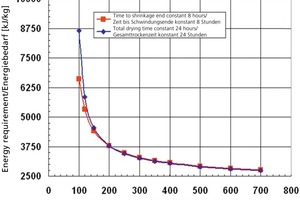

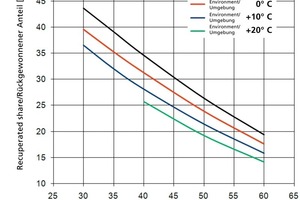

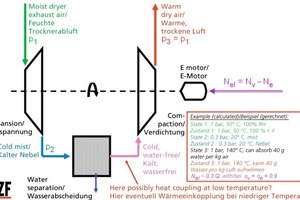

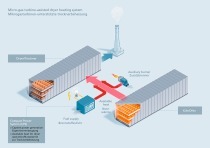

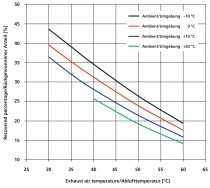

The article presents different possibilities for lowering the energy requirement during drying and thus for lowering the loss of exhaust air from drying plants. A description is given of how, with existing drying technology, a reduction of the energy requirement can be achieved. This concerns the widely used chamber dryers, but also continuous dryers. Since the dryer exhaust air is the greatest energy consumer in the brick plant, the article also deals with possibilities for heat recovery from the dryer exhaust air.