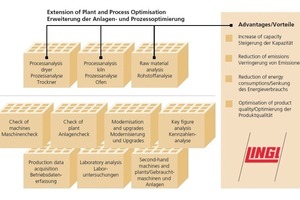

Cost reduction by process analysis

Lingl, the supplier of plants and machinery from Krumbach offers three central blocks in the plant and process optimization in its service quotation: Analysis of the raw material, process analysis at the dryer and process analysis at the kiln. Especially when modernizing plants the process analysis is an important prerequisite for the optimization of the complete plant as to the objective target of output quality and quantity improvement as well as to the reduction of emissions and consumptions.