Brickworks 4.1 will be a hybrid

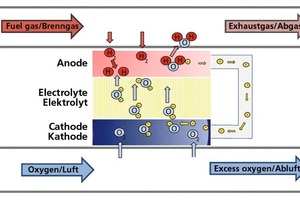

This article is devoted to explaining what future brickworks could look like. The main objective will be to maximize energy efficiency while coping with the fluctuating availability of electricity. Also described is how the brick and tile industry can make a macroeconomic contribution to the energy turnaround. By way of analogy to the German government’s Industry 4.0 concept, which is geared primarily to the networking of production processes, the goal here is to network the use of energy.

1 Introduction

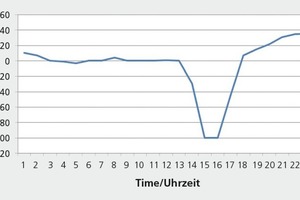

Energy efficiency is a hot topic, both politically and economically. The storage and/or flexible utilization of energy is gaining lots of attention now, too. As renewable sources of energy come into increasingly widespread use, but with substantial fluctuations in their availability, major demand has arisen for technologies with which to optimally coordinate the supply and demand of energy, most notably of electricity.

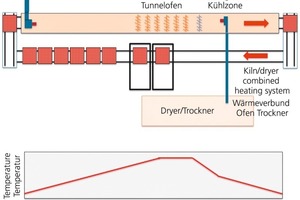

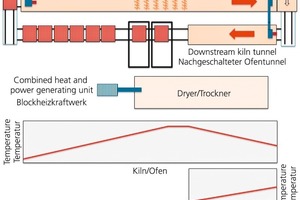

For economic reasons, only such technologies are discussed here that either can be integrated into existing facilities or are at least compatible with them. If so,...