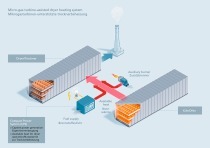

Combined kiln-dryer heating systems with thermochemical heat storage

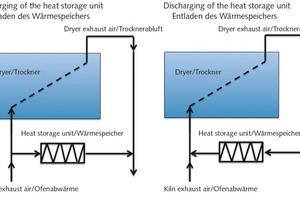

This article presents how thermochemical storage can be used to make energy supply to the drying process independent of when heat is available from the kiln and how hybrid heating can be realized.

1 Introduction

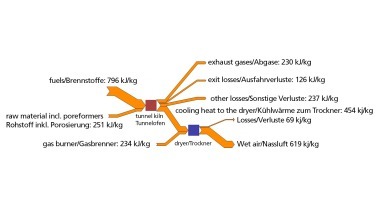

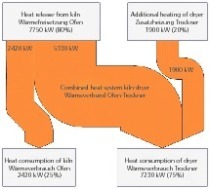

In Zi Brick and Tile Industry International 7/2015, the concept of a brickworks with a “hybrid-ring tunnel kiln” was presented, in which the kiln cooling/dryer combined heating system is replaced with a kiln exhaust/dryer combined heating system with maximized exergy efficiency. With hybrid heating and networked utilization of electrical energy, significant cost savings are to be achieved.

However, one problem always associated with combined systems is the under certain circumstances fluctuating utilization of the installed production capacities and the synchronization of the...