Developments in the recycling of clay bricks and brick masonry (Part 2)

Clay brick is a construction material with a long tradition. The further development of its product properties is the subject of a wide range of efforts. To confirm the sustainability of the construction material, the focus is now on its recyclability as a new issue. In collaboration with the clay brick and roofing tile industry, IAB Weimar and IZF Essen have worked on several aspects in related research. Part 2 concerns the use of clay brick as a substitute raw material.

4 Focus 2: Bricks as a substitute raw material

The focus here was the use of fine-grained broken bricks from building demolition as raw material components for the production of new bricks. As derived from the studies described in the literature [6], [7], [8], the particle size of brick flour used as a secondary raw material should not exceed 200 µm. The total sulphur content should remain below 0.5 mass%. Other requirements are related to the calcareous components, which are limited by the following recommendations:

Loss on ignition < 3 mass%

Calcium carbonate content < 10 mass% and

Content of mortar and concrete < 20 mass%

In contrast to these requirements, in the studies described here, coarser-grained variants were used as a substitute raw material to test whether a direct use of brick sands is possible without additional comminution. Moreover, besides unmixed bricks from demolition, recyclates from various recycling companies were also subject of the studies. These contained considerable contents of non-brick mineral components and did not always fulfil the above-mentioned requirements.

4.1 Material and methods

The recyclates come from different sources. Unmixed, used brick varieties, that can be classified in certain qualities, were selectively removed as rubble from building structures that were being prepared for demolition or actually in the process of demolition. In addition, unmixed brick rubble, which consisted predominantly of clinker bricks and roofing tiles, was supplied by a recycling company. The other used material came from different sources. The new brick rubble was available thanks to the “Filled brick recycling” research project (»15).

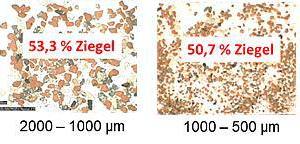

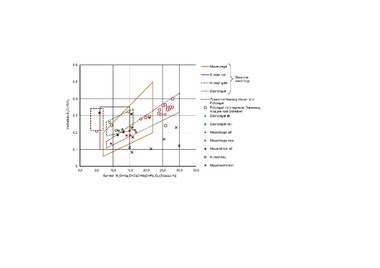

The procured recyclates were first sized in fractions smaller and larger than 4 mm. The fractions < 4 mm were characterized in detail in respect of those properties that are important for recycling as a secondary raw material. The total sulphur content was determined with a sulphur-carbon analyser, the CaO content by means of X-ray fluorescence analysis and the carbonate content by means of differential thermal analysis. The material compositions of the recyclates was analysed by counting the particles by colour under a digital microscope. Preliminary tests showed that, with this method, it was possible to differentiate between brick particles and mortar and render to a particle size of 250 µm based on colour. Above this limit, the brick content increases slightly with increasing particle size (»16). As described above, that is because of the easier comminution of the mortars and renders compared to that of the bricks. For the counting of the brick content, from all samples, the 1/2 mm fraction was selected. The composition of the recyclates from dismantling and demolition showed strong fluctuations. The brick content varied from 100% in the case of unmixed brick material to a brick content of approx. 20% in the masonry rubble. The new bricks had an average brick content of 80%. Other components contained in the mixes were in the case of the used recyclates mortar, render, concrete and some unidentifiable components. In the case of the new bricks, mortar, render and mineral wool remnants were present as minor constituents.

In the case of the recyclates, the samples that contained a low content of brick and high content of residual particles, exhibited higher values for the analysed parameters than the unmixed bricks (»Table 2). The recommended quality parameters were only partly met by these recyclates. For the new backing bricks, almost all parameters were exceeded.

From the originally available 18 recyclate samples, the samples C, D, H, R, T and V were selected as these represented a wide range of recycled materials. They were added to the three bodies used as base materials

lime-free roofing tile clay (DZ)

pyrite-containing facing brick clay (VMZ) and

high-carbonate vertically perforated brick clay (HLZ)

The amounts added reached a maximum of 10 mass% for the roofing tile body while up to 25 mass% was added to the backing brick clay. Selected properties of the base materials are summarized in »Table 3.

The particle size distribution of the starting materials has crucial importance for brick production. It influences the quantity of the required mixing water, the shrinkage behaviour, the drying properties, and the firing behaviour. The contents in the fractions 2 µm, 2–20 µm and > 20 µm serve as a benchmark for evaluation. Here, there are major differences between the recyclates and the bodies (»Table 4).

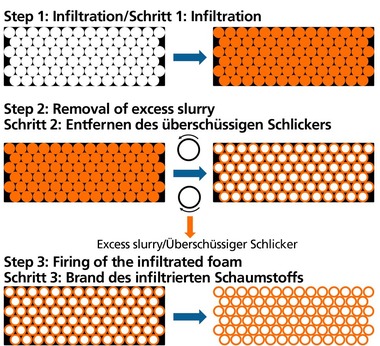

To determine the effects on the product properties, recyclates were added to the bodies, the amounts added being oriented to the requirements to be met by the specific product. In the case of the roofing tile bodies, a maximum of 10 mass% was substituted with the recyclates. In the facing and vertically perforated brick bodies, on the other hand, up to 25 mass% was substituted. From the batches, cylindrical specimens with a diameter of 33 mm were produced in a laboratory extruder and then fired in a gas-heated muffle kiln in accordance with the firing curves used in the respective production plants (»17).

Before being fired, the specimens were tested to ascertain their dry shrinkage and flexural strength. For the fired specimens, the density, the water absorption, the firing shrinkage and the flexural strength were determined. The appearance of the fired specimens was appraised, especially in respect of the occurrence of lumps of lime and efflorescence. Tests on eluates with a water-solid ratio of 10 to 1 were performed to evaluate environmentally related properties.

4.2 Results

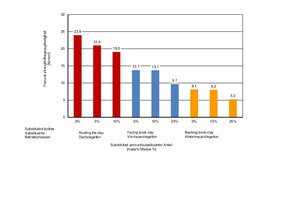

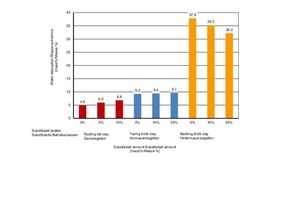

In case of the recyclates used for substitution, it is possible to differentiate between unmixed varieties recovered from roofing tiles and those with mineral impurities. With the addition of unmixed crushed roofing tiles to the roofing tile clay, already at 3 mass%, a decline in the strength and an increase in the water absorption were observed. The facing brick and vertically perforated brick clays were more robust (»18, 19). Up to a substitution of 10 mass%, no decrease in strength could be observed. Water absorption did not change or decreased. The body became denser.

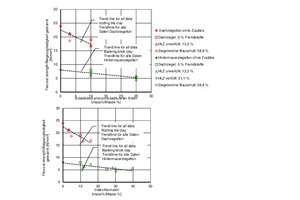

With the addition of varieties with minor constituents, the substituted content was not sufficient as an index because in this way it was not possible to take the impurities explicitly into account. The sum of the substituted amount and impurities introduced as a result, is used as an auxiliary variable. With a substitution of 10 mass% with a content of impurities of 20 mass%, this index amounts to (10 + 10 x 20/100) mass% = 12 mass%. Plausible dependences result between this index and the properties of the fired specimens. At the same substituted amount, the substitute with more impurities leads to a stronger decline in strength than that with a low content of impurities (»18). With this formal approach, it is not possible to take account of how the type of impurities influences the properties (»20).

Another important quality characteristic is the visual appearance of the fired products. In the case of the roofing tile clay, a system can be identified. Substitutes with no or only a low content of impurities can be added in quantities up to 3 mass %, without any impairment of the visual appearance (»Table 5). Already crushed brick D, which contains 13.3 mass% impurities, leads in the case of 3% substitution to “lime lumps” to a limited extent. If 10% of the roofing tile body is substituted with recyclates, impairment of the visual appearance is established for all substitutes. In the case of the other products, hardly any tendencies could be identified. The impairment of the appearance does not always increase with the quantity added. In three cases, even some improvements result with higher added quantities.

In the scope of the eluate analyses, the leaching behaviour of the specimens with an addition of 10% RC materials was tested. Both the values in respect of heavy metals and soluble in water salts can be classed as harmless, although the particle size in the sample preparation was selected to be much finer than specified in the relevant testing regulations. As a result, the surface area available for elution is much bigger than that for the particle size required in the relevant standards.

4.3 Recommendations

From the results presented, it can be concluded that the bodies for brick production can be substituted to a certain extent. The extent of substitution depends both on the product and the properties of the substitutes. No more than 3 mass% crushed unmixed roofing tile should be added to the roofing tile clay so as not to impair the quality of the products. On the other hand, for the production of backing bricks, substitution up to at least 10 mass%, even with a high content of impurities, appears possible.

The presented results should be explored further with tests on the influence of the impurities and the particle size. In systematic tests, the effects of the type and percentage of the impurities on the brick quality should be determined, to make the index defined here more useful. All substitutes in the tests described were sands with particle sizes to 4 mm. They were very coarse compared with the bodies. According to the literature references, grinding of the substitutes leads to much improved results. The compressive strength increase ranges between 10 und 30%, when the additive materials with an original 90% undersize particle size of 0. 5 mm is ground to a x90 particle size of 0.15 mm [9]. This potential for improving the properties and, where appropriate, higher substitution quotas should be the subject of future studies.

Acknowledgement

The results are based on research work (AiF-ZIM, AiF-IGF, EuroNorm) funded by Germany’s Federal Ministry for Economic Affairs and Energy. We should like to thank the project sponsors for the financial support. Thanks are also due to the industry partners involved for their support of the research projects like Ziegel-Kontor Ulm GmbH Thermopor, Deutsche Poroton GmbH, Mein Ziegelhaus GmbH & Co. KG, Deutsche Rockwool GmbH & Co. KG, Wienerberger AG, Schlagmann Poroton GmbH & Co. KG. We thank Brick Research Institute Essen Regd for the good professional cooperation.

References in part 1, Zi2/2020.