Do counterflow kilns hold the promise

of an energy miracle? (Part 1)

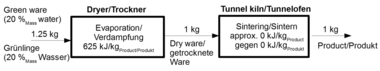

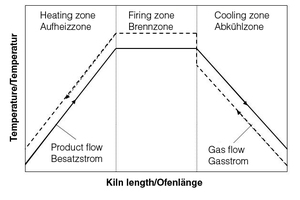

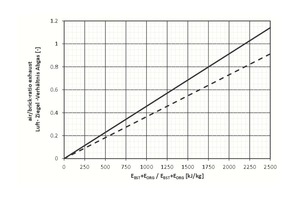

The theoretical principles governing the energy consumption of counterflow kilns are explained and compared with the actual performance data of existing counterflow kilns. In addition, the advantages and disadvantages of different types of counterflow kilns are discussed and their energy conservation potentials compared with the energy consumption of fast firing kilns.

1 Introduction

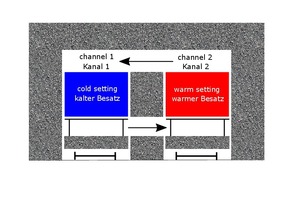

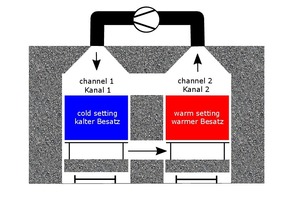

According to research by Böger [2], Carl Emmel was awarded German Imperial Patent No. 13604 on May 1, 1880, for his counterflow kiln. The first reference to a foreign patent found by this author was made by Conrad Dressler on July 1, 1924 [3] concerning a tunnel kiln with two parallel channels through which trains of kiln cars travel in opposite directions (»1). It is not known whether a kiln of the type described was ever actually built.

In the 1930s and ‘40s, Riedhammer, Kerabedarf and Siemens-Schuckert built a number of counterflow kilns, some of which were electrically heated...

![»1 Drawing excerpted from Conrad Dressler‘s patent specification for a double tunnel kiln in the year 1924 [3]](https://www.zi-online.info/imgs/1/3/2/6/9/4/2/tok_0b285e8bb16c1f466c49e2780666a6ef/w300_h200_x289_y196_Zi2_Vogt_Bild_1-57b0e550eb61f996.jpeg)

![»2 Electric counterflow tunnel kiln by Kerabedarf in Nieder-Ullersdorf, 1938 (from [2])](https://www.zi-online.info/imgs/1/3/2/6/9/4/2/tok_9cca9f2d172afe1f1ba7af2c915e647b/w300_h200_x317_y400_Zi2_Vogt_Bild_2-581e65bf2a09bd05.jpeg)

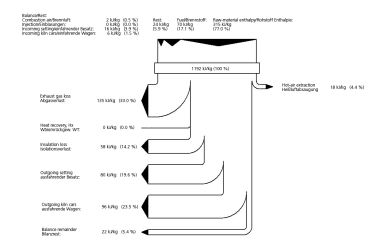

![»7 As-found mass flows and temperatures characterizing the air balance in the Grechwitz counterflow kiln [9] (optimized state)](https://www.zi-online.info/imgs/1/3/2/6/9/4/2/tok_b44aded45846640870c51cdeae64952d/w300_h200_x600_y295_ZI2_Vogt_Bild_7-65cac74a5d1fc187.jpeg)