Hybrid-ring tunnel kiln with flue-gas-based combined heating system: 65% savings on energy – a concept study

In its 6/2015 issue, Zi Brick and Tile Industry International presented the Brickworks 4.1 concept in which hybrid heating and networked production and use of electricity yield significant cost reductions. The present contribution explains how brickworks can be operated with maximum utilization of the exergy content of primary energy sources – in addition to energy networking and hybridization – in order to achieve maximum possible energy and cost efficiency.

1 Introduction

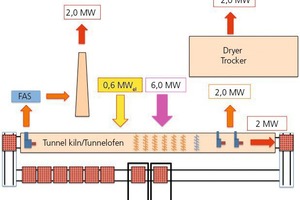

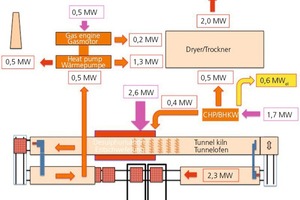

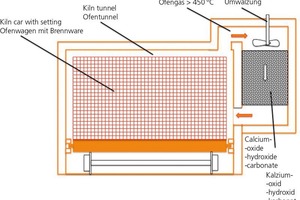

The concept begins by dissolving the kiln/dryer combined heating system, instead supplying the dryer with energy via exergetically optimized heat flow from the kiln exhaust and power generation. The dissolved kiln-cooling/dryer combined heating system is replaced by a kiln-exhaust/dryer heating system.

A hybrid arrangement allows to choose between electric heating when electricity prices are low and, on normal operating mode, power generation both for captive use and feed-in to the public power grid.

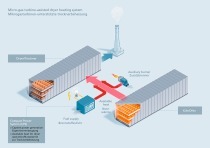

The concept is also geared to converting and supplementing existing facilities...