New concept for better heat transfer in the cooling zone (and elsewhere)

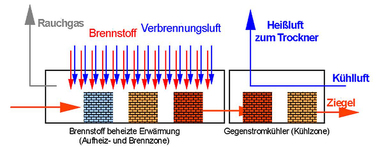

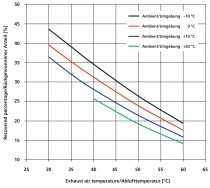

Today‘s tunnel kilns handle relatively large volumes of air and exhaust. Low exit losses are achieved at the cost of high cooling-air volumes that have to be drawn out of the tunnel kiln and dried asynchronously to the firing operation. Especially in the manufacture of clay roofing tiles fired in H-cassettes, the dryer can make full use of that hot air. In a joint project, the IZF Brick and Tile Research Institute Essen, the University of Magdeburg and RWTH Aachen University are working on a concept with which to significantly reduce those air volumes and to ready the concept for application to existing facilities.

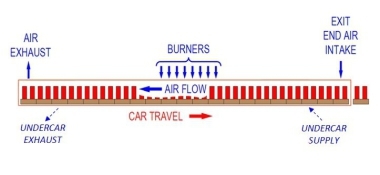

The idea is to install hot air fans inside of the firing channel. This minimizes the fans‘ power requirement, and the loss of pressure in the otherwise normally required piping can be avoided. Hence, large volumes of air/gas can be handled and heat transfer improved with only a modest amount of power.

Dipl.-Ing. E. Rimpel, Brick and Tile Research Institute Essen Regd