The potential of the replica technique for the clay brick and tile industry

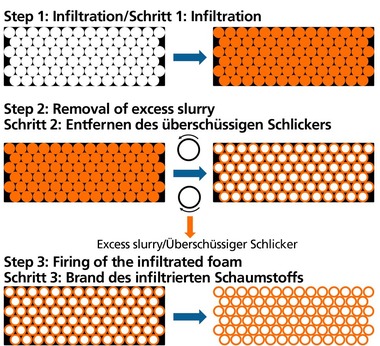

In this process, an existing structure is replicated, in that an open-pored, organic body, termed the template, is infiltrated with ceramic slurry and excess slurry is then removed by squeezing or centrifuging. Then the body is dried. Drying is followed by a firing process, in the course of which the organic component burns off, leaving a solid ceramic to form. As a template, both natural materials, like wood shavings, and synthetic materials, like foams, can be used. With the choice of the templates and the use of mineral and chemical additives, the properties of the ceramic can be influenced. The ceramics formed have high porosity and therefore offer possibilities for production of thermally insulating and noise-absorbing products.

Dipl.-Ing. (FH) Alexander Winkel M. Sc., Brick and Tile Research Institute Essen Regd.