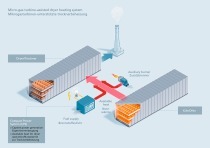

When, as a result of increasing energy prices, the costs incurred for the energy-intensive process steps of drying and firing rise, measures for energy saving and the economically efficient use of energy become more interesting again. In the first place comes the reduction of the specific energy consumption of kilns and dryers by means of process measures. Second comes the use of waste heat in other process steps in the brickworks and then waste heat utilization and conversion into other usable energies.

Owing to the established integrated heat supply between kiln and dryer, the dryer is...