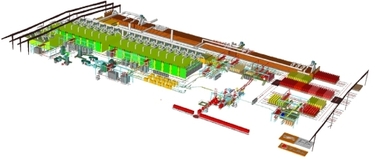

New roofing tiles unit for Erlus AG in Germany

To meet demand for Erlus AG’s high-quality roofing tiles, the company has invested in a new production line. Thanks to its expertise in firing and automation, Cleia was selected to realize this project within just nine months. This included the replacement of the stationary U-setter firing technology of line 4 at Plant 2 in Neu-fahrn with a new H-setter production line.

The ambitious plan to start up the production plant before summer 2013 after the order had only been placed in September 2012 was successfully realized.

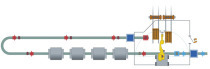

New generation of kilns with water seal

Erlus AG has been using water seal kilns since 1990 and has always remained faithful to this technology as it delivers excellent firing performance. With the successful achievements of Cleia in Algeria, Poland and Portugal where a Hydro-Ecofast kiln had just been put into service at a roofing tile plant, Cleia was able to demonstrate how the quality of the design and services had been further improved.

The Hydro-Ecofast kiln consists of prefabricated elements and was assembled on site during the demolition and civil engineering work. Assembly was started in January 2013. The first fired roofing tile left the kiln in June 2013, less than 6 months after construction had begun.

Evolution of automation engineering

The installations supplied by Cleia feature the latest technological developments and are mostly equipped with servomotors and transmission by timing belts. The machines are more precise and react more smoothly so that they can be started up again much more quickly in the event of a fault or emergency shutdown. These new features have also significantly reduced machine noise.

Tiles and accessories produced simultaneously

New in this installation is that flat accessories are produced at the same time as the actual roofing tiles. After they have been fired, the accessories are recognized by the system and split off from the roofing tile line. In a dedicated line they are packaged under beam forms and then palletized on the standard line. This function facilitates production management for this type of accessory.

Reduced energy consumption

The latest technical developments from Cleia enable a 10-% reduction of energy consumption compared to the last equipment delivered to Erlus AG. This results from the installation of innovative technologies:

› Ecofast kiln with optimum insulation thanks to new superstructures and setting arrangement

› Kiln extraction and overpressure distributed over several points

› Hot air supply for air combustion to the burners

› Individual ventilators controlled by variable speed drives for each firing unit

› High speed roof burners from the “Top Jet” range

The construction and installation of this new production unit were completed in perfect coordination and partnership with the technicians, plant operators and project management at Erlus AG. Cleia supplied a successful installation completely meeting the expectations and quality standard for Erlus roofing tiles, while significantly reducing operating costs.